INAC US’s Tech Strength Series 02

Transparent/Clear

3D Printing

A special section introducing our one-of-a-kind technology

The theme of the second feature is “A 3D printer for stylish and detailed parts!”

We propose the best transparency products by selecting the optimal conditions and processing methods for your particular use case.

INAC’s wide range of technologies enables us to produce all sorts of transparent parts using 3D printers.

Undercut parts can also be created in one piece

The best feature of 3D printers is that they can create undercut and hollow shapes in one piece, which is impossible with conventional cutting. Bottle shapes like the one in the photo can be produced in one piece, allowing the contents to be visible without risk of liquid leakage.

Another great feature is the short delivery time. Since there is no need to arrange materials or create processing programs, we can respond to urgent orders as long as we have 3D data.

This method is ideal for when you just need products quickly.

"The combination of design flexibility and finishing technology makes it ideal for stylish components"

Beauty that defies the image of conventional 3D printers

3D printers are attractive for their freedom of design, but products that have just come out of the printer still have supports and traces of lamination, and are not very appealing to look at.

At INAC however, we use our accumulated experience in techniques such as polishing, yellowing removal, and transparency processing to achieve a beautiful finish, so creations can be used for various purposes such as for creative design parts.

We can also make products transparent even when the inside is inaccessible, such as the case with bottle shapes.

Please consult with us even for designs that you have previously given up on as being unfeasible to produce.

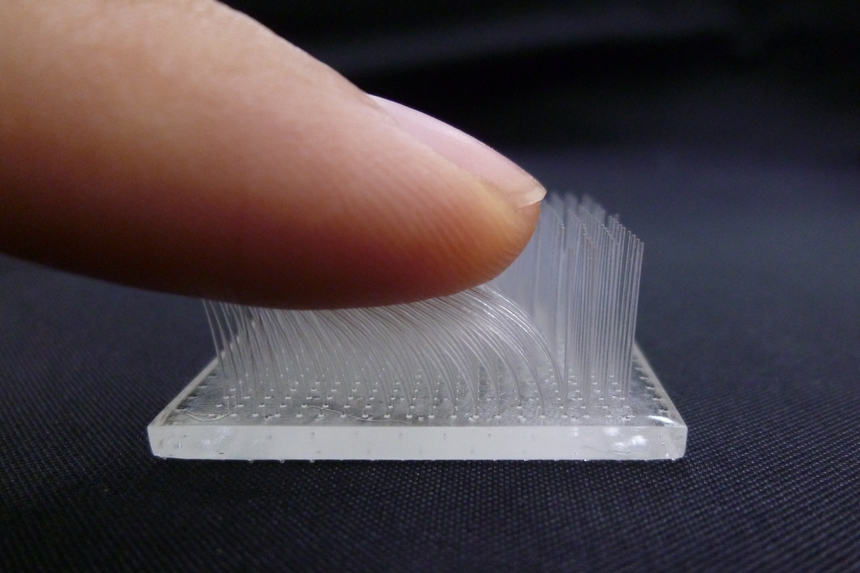

High reproducibility of detailed shapes

3D printers are easy to use, but it is surprisingly difficult to make them work the way you want them to. And when it comes to finely detailed fabrication, simply reducing the laser diameter is not enough to reproduce shapes perfectly.

INAC’s operators are familiar with equipment of a wide variety of parameters and are able to maximize performance. Leave it to use to produce difficult shapes such as fine brushes.

High quality and quick delivery of design exhibition models

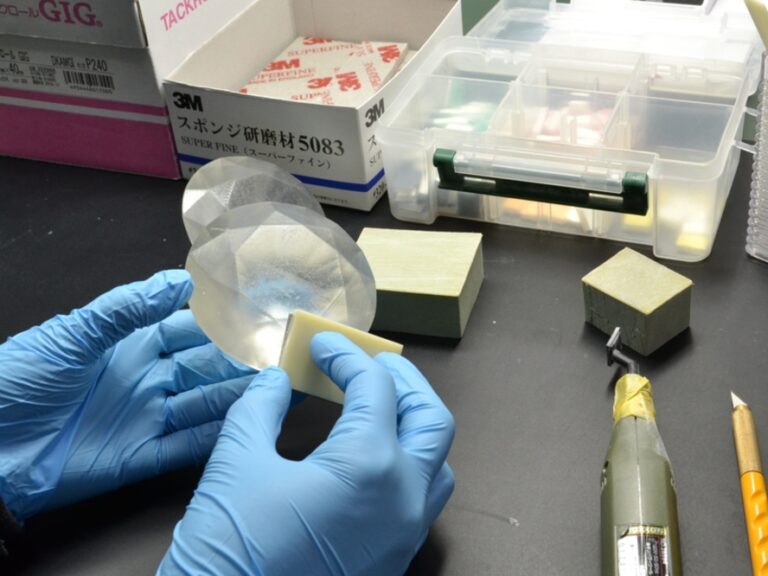

[Round Brilliant Cut Models] High-transparency, high quality, achieved in the shortest

We deliver high-quality, high-transparency 3D printed components.

High clarity (bubble-free)

* Due to the production method, fine air bubbles may be present in rare cases.

Colorless (high transparency)

Visible light transmittance: 90.4% (10mm thickness)

Refractive index: 1.512 (wavelength 587.562 nm/horizontal direction) K7142 compliant

Heat resistant temperature: 53°C (low load) K7191

Hardness: D83

The combination of “Highly transparent material” + “Elimination of yellowness” will result in the production of clean transparency and sharp edges.

Use the products as high-quality design models.

Examples applications

- Design models for exhibitions

We faithfully reproduce complex shapes that are difficult to manufacture by cutting, giving

Models for design review

These can be delivered in an ultra-short delivery time, so they can be used to shorten the time for design decisions. We even have a track record of next-day delivery.Internal validation models

These can be used for quick cause investigation and verification, such as for quality improvement and design changes. Being able to directly observe internal operation and interfering parts can result in validation with confidence.

[Car 1/10 Mockup] High quality transparent models

A surprisingly transparent model that absolutely minimizes internal air bubbles!

- We can provide “ultra-short delivery times” thanks to our 3D printers.

- Please feel free to contact us when you urgently need another exhibit at an in-house exhibition or event.

Production Process Flow

①Detailed meeting (We will visit your company or have a meeting through an online platform such as Zoom)

The meeting will include an explanation of the production method, among other topics, based on the purpose of use and specifications.

Depending on your request, we will provide samples and conduct a simple investigation of the resistance to chemicals and the like to which the product is to be exposed.

②We will ask you to supply 3D data.

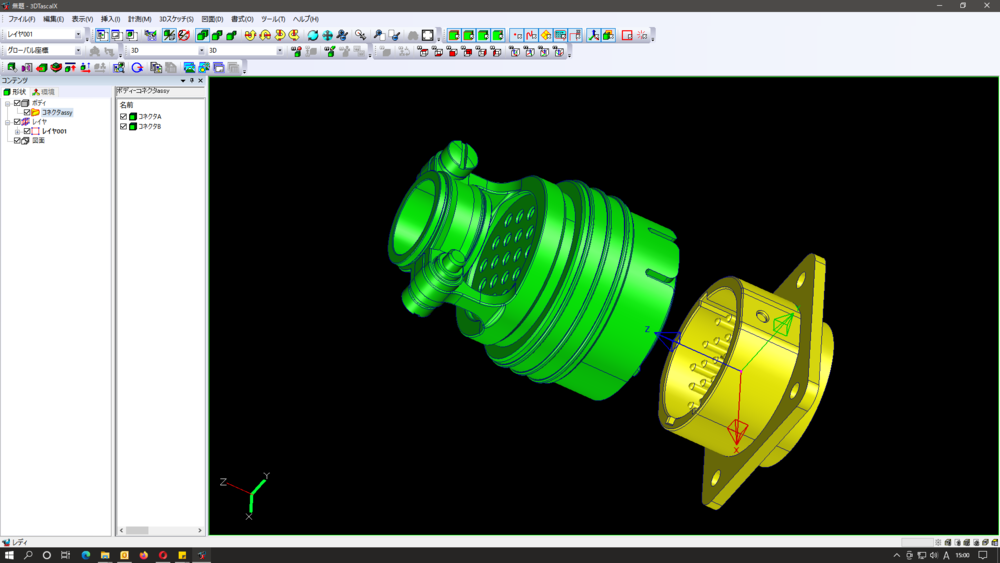

③Creation of programs for 3D printer output ← Our know-how

We aggregate many 3D printer output parameters and program them with specialized software to determine how the product shape will be formed.

④3D printer output

The shape is completed by irradiating the part to be shaped with UV laser light and repeating stacking. In general, the lamination pitch is around 0.1-0.15mm with the minimum being = 0.05 mm. If the lamination pitch is finer, it may look nicer, but it would take more time, so a balanced approach is important.

⑤Completion of 3D printing output

In order to maintain the shape of the product during output, “support structure” is added while printing. After printing, the product is cleaned to remove the unnecessary “support structure”.

⑥Finishing touches

Layer ridges are removed by hand finishing in order to create a smooth surface.

If transparency is not required, the product is delivered in this state.

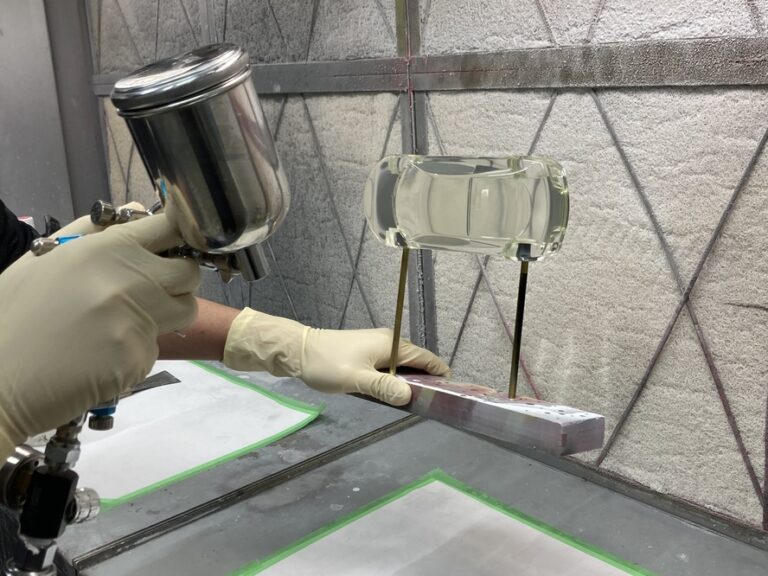

⑦Finishing touches using clear coating (Completion)

Clear coating creates a clear and transparent product.

[Connector parts] 3D printer output of parts with finely detailed shapes

Reproduction of fine shapes such as lock mechanism

- We can reproduce detailed internal shapes that are difficult for a cutting process to reproduce.

- Leave finely detailed shapes to us.

- We can produce scale models, and can provide modified model sizes suitable for your application.

- These models can be used for pre-assembly checks or for educational purposes.

Production Process Flow

①Detailed meeting (We will visit your company or have a meeting through an online platform such as Zoom)

We will inquire about your use cases and special requests, and then decide production specifications such as finishing level and decoration.

②We will ask you to supply 3D data.

.stl .igs .x_t .stp; For others, please consult us.

③ Creation of programs for 3D printer output

We can accommodate from the minimum lamination pitch of 0.05 mm. Optimal programming is performed in consideration of the balance between precision and delivery time.

④ 3D printer output

We set the parameters for the 3D printer to output the product, taking into consideration the environment at the time of production, including UV laser beam diameter/output, material level control/coating conditions, environmental temperature/humidity, among other conditions.

⑤ Finishing and clear coating

Unnecessary “support structure” will be removed and the product finished, and if required, a clear coating will be applied for transparency.

* We select clear coating depending on the usage.

⑥Final shipping inspection

We deliver the products to our customers after visual inspection and measurement so that they can use them with confidence.

We also check the fitting of the parts ordered as an assembly before shipping.

[Front Grille] Large parts can also be created by 3D printers

This is an original design of an automobile front grille.

Transparency processing and masking paint were applied to the 3D printed model.

Product size: 400 x 800 x 155

The maximum molding size is 600 x 800 x 400.

Large parts with undercuts can also be processed in one piece.

This can be combined with decorations such as painting.

Our company also offers painting and vapor deposition plating in-house which enables us to freely combine 3D printing and decoration.

The condition of the substrate greatly affects the finish of the painting, so we are proud that one of our strengths is that we apply an appropriate substrate treatment to best suit the post-processing.

We will decorate according to your requests which may include, for example, toning to match a color sample.

Please feel free to contact us for mock-up production.

Our sales representative will contact you as soon as possible.

* Required.

* The attachment’s total maximum size is 30 mb. Use shift or ALT key to select multiple files.

Information entered here is used for information purposes only.