3D Printing Service

What We Offer

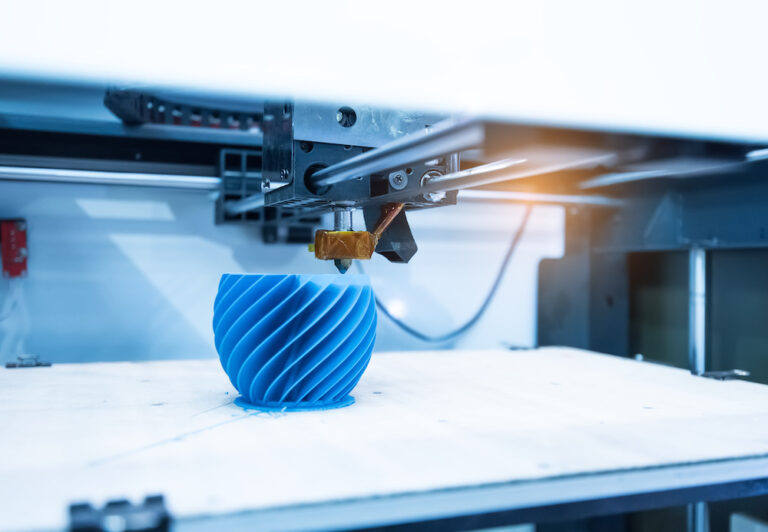

3D printers can be used to create products with complex shapes in a short period of time.

They can be used for a wide range of applications, including industrial applications such as shape verification, visualization parts, and master models for casting.

Additional work can be performed at a CNC machining center after modeling to increase the precision of some parts.

Depending on the shape, cost advantages can be achieved by combining the technology with machined or molded parts.

Why Choose Us

Materials for 3D Printing

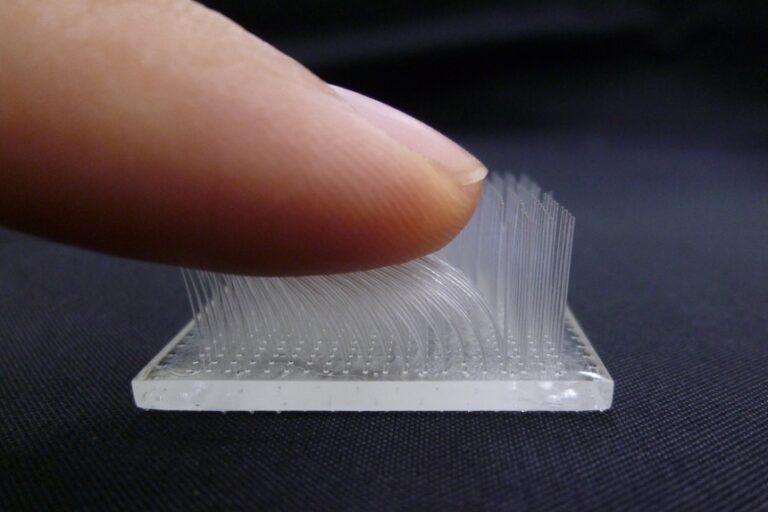

Clear Plastic

A highly moisture-resistant resin with high transparency that can be used in water or in highly humid environments without any change in dimensions or physical properties.

It is suitable for visualization models such as flow path models because it exhibits very little change over time due from moisture absorption.

3D Printing Methods

Stereolithography (SLA)

Stereolithography(SLA) is a modeling method for 3D printers in which a tank of liquid photocurable resin is irradiated with ultraviolet laser light with the purpose of being able to harden and stack layers one by one.

Selective Laser Sintering (SLS)

Selective Laser Sintering(SLS) is one of the more prominent modeling methods for 3D printers. It is a method in which a powdered material (resin or metal) is irradiated with a laser beam and sintered layer by layer, to form a shape.

3D Printing Tolerances

Stereolithography (SLA)

| Specifications | Value, inches |

|---|---|

| Max Part Size | D31.50/W23.62/H15.75 |

| Min Feature Size | φ0.394 |

| Tolerances | ±0.004 |

Selective Laser Sintering (SLS)

| Specifications | Value, inches |

|---|---|

| Max Part Size | 13.39×13.39×24.41 |

| Min Feature Size | φ0.394 |

| Tolerances | ±0.012 |

CNC Machining Applications

Shape confirmation

Products are manufactured for model verification in the initial stages of product design. Generally, a short delivery time is required.

Mock-ups

We specialize in the production of mock-ups for use in exhibitions and presentations.

We can also produce mock-ups from sketches without data or drawings.

Master-models

Used as a prototype for vacuum castings. We can handle the entire process in-house, including finishing using a surfacer.

Finishing Options

| Support removal only | Removal of supports for shape verification. This process is inexpensive and can be performed in a short period of time. |

|---|---|

| Transparency | The surfaces are hand-finished with sandpaper and then clear coated to make them transparent. It may be difficult to achieve perfect transparency inside holes. |

| Finishing using surfacer | After the surfaces are hand-finished with sandpaper, they are coated with a surfacer. |

Past Works

Auto-wheel

Auto-wheel manufactured with transparent stereolithography technique

Special technique enables highly transparent 3d printing with minimum bubbles.

Delicate texture is also available.

Φ300mm*130mm (1/2 of original size)

The Statue of Liberty

Fine shape like miniature model can be 3d printed in house.

Material: TSR 829 (Moisture-resistant highly transparent materials)

Size: 11mm height without support

Nylon (SLS)

MATERIALS: PA2200 – Polyamide 12 (nylon)

Balanced part property profile characterized by strength, rigidity and good chemical resistance.

FAQs

We can create shapes that cannot be reproduced by cutting, and we can do so with short delivery times.

The materials that can be used for production are limited. For specific special materials, we recommend cutting.

The durability will be lower than that of machined products. In the case of TSR829, the heat resistance is approximately 50℃. Please contact us for details and we will provide you with physical property tables.

(Note: The physical property tables will be uploaded to the website at a later date)

We can ensure transparency enough to use it for visualization experiments. Some shapes, such as the inside of holes, may be difficult to finish perfectly, resulting in reduced transparency in those areas. Please refer to the sample portfolio for details.

Get In Touch!

If you have something you want to make, please contact us. Even a rough idea is OK.

We will give shape to your idea and deliver it to you. Please feel free to contact us.