Vacuum Casting Service

What We Offer

The vacuum injection method uses a silicon mold instead of a metal mold to inexpensively duplicate a product. If the actual product is available, the same shape can be produced even without 3D data.

The feature of this method is the ability to produce rubber-like and colored products. The vacuum injection method enables extremely short delivery times by using in-house 3d printers to produce the master model.

Why Choose Us

Short lead time

By using a 3D printed model as a master model for the vacuum casting process, it is possible to deliver in the ultra-shortest time.

Materials for Vacuum Casting

ABS like

(urethane based)

ABS-Like, a versatile polyurethane plastic, closely simulates the properties of ABS thermoplastic, making it an excellent choice for a wide range of parts produced through vacuum casting.

Acrylic like (urethane based)

Acrylic like vacuum injection products are transferred directly from the quality of the master model, so the transparency is derived from the master model. The disadvantage is the tendency to tarnish compared to actual acrylic.

Elastomer like (urethane based)

Elastomer like is available in a choice of hardness in 5 degree increments. This material can be colored or made transparent.

Tolerances

| Tolerance | ±0.00394 inches |

|---|---|

| Maximum part dimensions | 39.37/31.50/59.06 inches |

| Minimum wall thickness | 0.03937 inches. |

| Duplication quantities | 20 (10 for transparent material) |

Industries Served

Vacuum Casting Applications

Design check

The vacuum injection method allows the production of prototypes of the same shape in different colors at a low cost. This method is used by designers to study color variations.

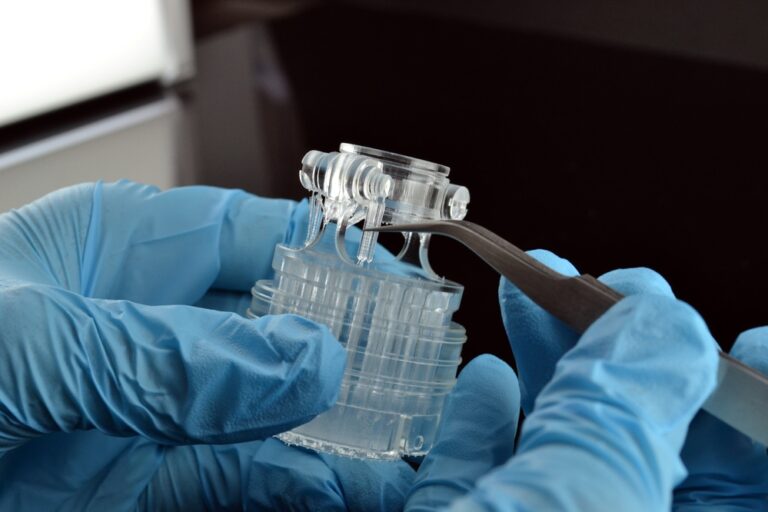

Visualization Model

It is possible to produce a transparent product without 3D data or drawings because an inverted model can be created from the actual product and duplicated. By visualizing the inside of a machine or robot, it contributes to the detection of defects and streamlining of maintenance work.

Small lot manufacturing

Suitable for small-lot production of parts that do not necessarily require a mold. Approximately 20 shots can be produced from a single silicon mold.

Finishing Options

| No finishing | Surfaces will have the same finish and texture of the master model. |

|---|---|

| Blasting | By applying sand or walnut to the surface, the surface is made pear-like. The finish will resemble graining texture. |

| Painting and Plating | Paint or plating can be applied through special pretreatment before decoration. |

Past Works

Simultaneous multi-color vacuum casting

We can handle sizes up to about the size of the front grill of a car. Most have one color, but we have the technology that allows multicolor casting such as two colors and three colors.

Toning vacuum casting (transparent to clear color)

Vacuum cast items can be colored and toned in accordance with color sample.

Color Variation: Clear, clear color, solid color, Pearl color, Glitter

Material Variation: ABS like, PP like, Acrylic lik, Elastomer

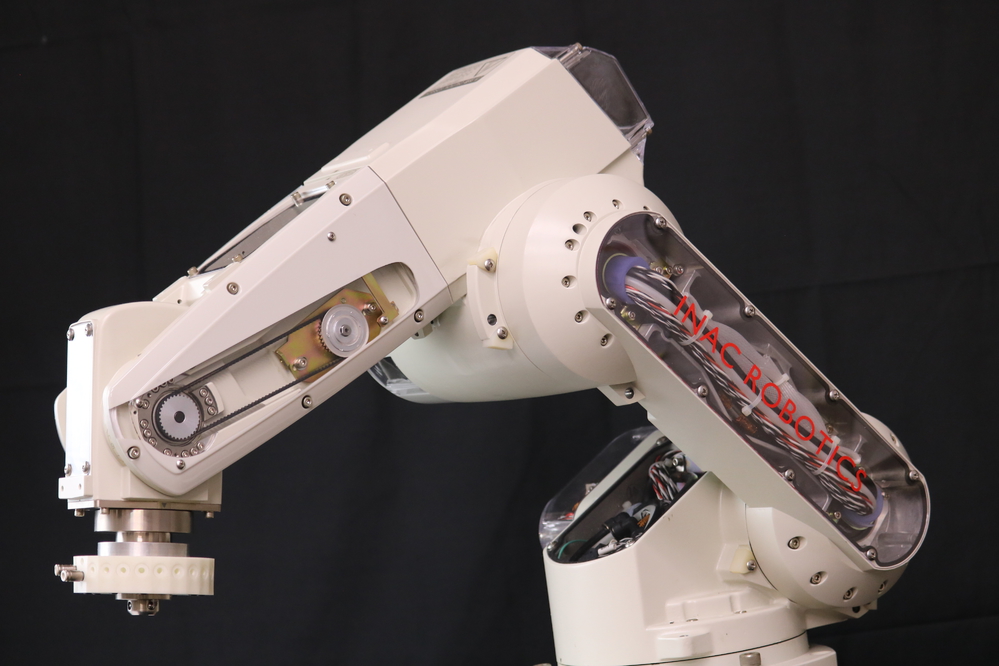

Transparent vacuum casting

Mock-up design utilizing partial visualization of robot arm. The transparency of the robot arm cover visualization allows greater ease to check the status of internal mechanisms, improves maintainability and reduces inspection times.

FAQs

Yes, it is. It is possible to manufacture without 3D data or drawings because we can create an inverted mold from the actual product and duplicate it.

All products manufactured by the vacuum injection method are made of polyurethane resin. There are various grades of polyurethane resin, such as PP-like, ABS-like, elastomer-like, etc.

Compared to metal molds, the cost of molds can be significantly reduced. Also, silicon molds are soft and can be used for complex shapes such as undercut shapes.

Roughly 5 to 200 pieces.

It is about ±0.004 inches relative to the master model.

Get In Touch!

If you have something you want to make, please contact us. Even a rough idea is OK.

We will give shape to your idea and deliver it to you. Please feel free to contact us.