What you can imagine can be created

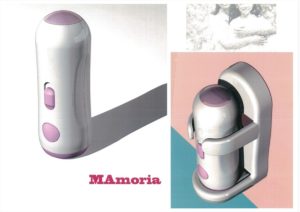

Planning · design · modeling · mechanical / housing design

Manufacturing unique and innovative designs by your designers often requires drawing of built-in mechanisms and housing.

Well–versed designers in our Design and Development Department can work directly with your designers to make proposals on prototype production as well as mass production.

- We will design based on sketching, drawing or concept.

- Our wide scope of manufacturing services includes new product development designs, mechanism designs, exhibition models, in-house exhibition models, jigs for assemblies, experimental devices, and miscellaneous devices.

- We also offer a one-stop service from model design to prototype production.

- We convert your ideas to CAD data to utilize its virtual images and designs and to support you in mechanism designing.

Resin · iron / non-ferrous metals machining

- Simultaneous 5-axis control by DMG Mori Seiki 5-axis machining center with high rigidity enables us to integrally process the whole parts with high-precision in one pass.

- Our machines correspond to a wide variety of materials (engineering plastics / super engineering plastics / ferrous and non-ferrous metals).

- Introduction of FF / eye CAD / CAM makes it possible to process products with fine shapes and huge data capacity.

♦ Typical resin materials

♦ Typical ferrous / non-ferrous metal materials

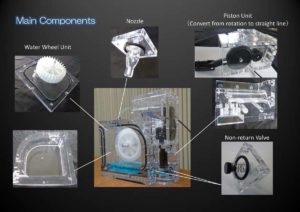

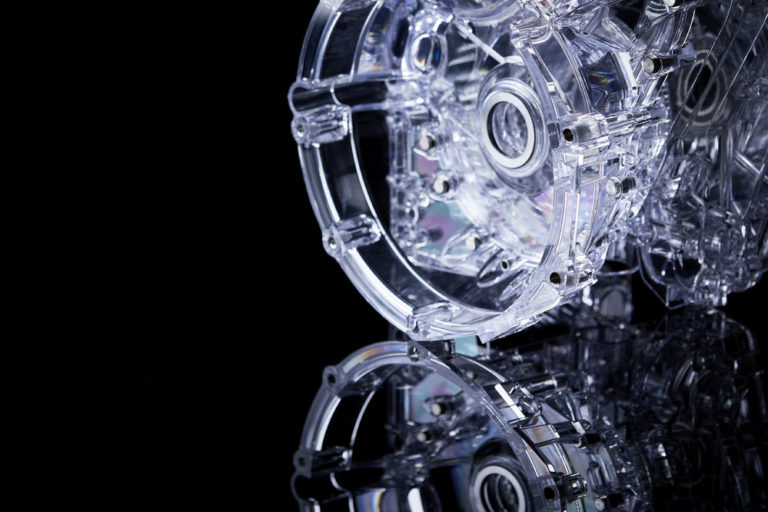

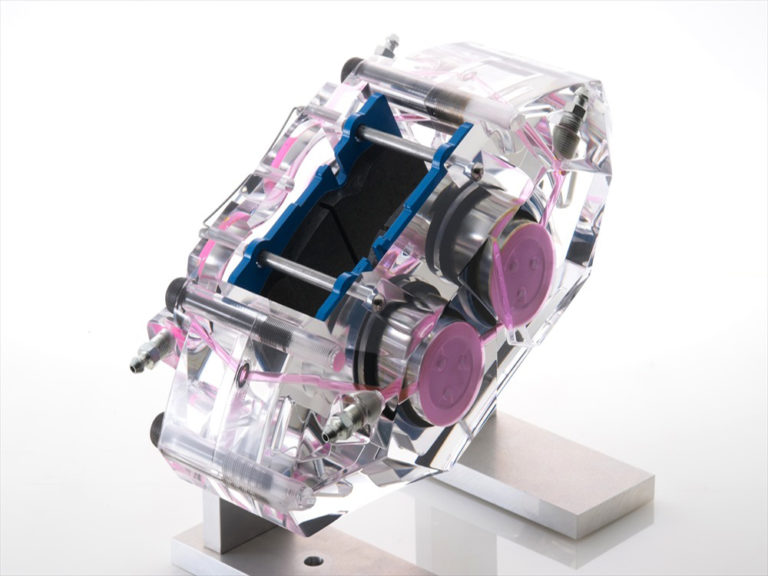

High transparency polycarbonate machining

♦Our strengths

♦Examples

- Transparent external cases on mechanical equipment for flow analysis

- Display models with a transparent external case for visualization of internal mechanical components

- Tutorial and educational purpose models.

- Lens parts for equipment such as headlight, tail light, etc.

High transparency acrylic machining without polishing

■ Characteristics of acrylic (PMMA)

Acrylic resin is noted for its high degree of transparency (approximately 93%) which is more transparent than glass (approximately 90%).

It is well-suited when creating models that require intricate designs, such as a monument.

◆ Our strengths

We machine acrylic products using an end mill manufactured in collaboration with a top quality blade-making firm, ensuring precise cutting.

This method eliminates the necessity for manual polishing, which can diminish dimensional accuracy, resulting in high machining precision.

In particular, transparency can be reproduced even for detailed shapes such as lens cuts, leading to the possibility of producing outstanding lens cut models.

In addition, cutting processing is performed by the dry cutting method. Therefore, the adhesion of chemical substances contained in the cutting fluid can be minimized.

♦Examples

- Our work of “Variations of Time” exhibited at Milan International Furniture Fair [Milano Salone]

- Experimental micro-channel flow models such as a microscope and a camera for observation of fluid flow channels

- Exhibition models featuring design, including monuments

- Lens parts for transport equipment such as headlight and tail light, etca top quality

Transparent stereolithography (3D printing)

3D printing enables us to manufacture products with bottle shapes and undercut shapes, which cannot be done in our machining center.

This would be the best method for complex structured products and design models that require verifying in the shortest possible time.

♦ Materials used

| ♦ Stereolithography (3D printing)

|

♦ Process overview

- 3D data is provided

- Create a modeling program (optimization of stacking sequences and attached supports during printing process/optimization in various modeling conditions) ← Know-how]!

- Printing

- Finishing (supports removal, layer lines removal, and hand polishing)

- Transparentizing (clear coating)

- Finished product (coloring and plating processes are available)

♦ Characteristics

- Our SLA machines handle from small to large parts (handling up to approximately the scale of a car front grille cover)

- Even complex shapes can be manufactured in a short delivery time.

- Used for design consideration that requires quick delivery.

- Decorations such as coating and plating can be applied.

Vacuum casting

By using a 3D printed model as a master model for the vacuum casting process, it is possible to deliver in the ultra-shortest time.

♦ Process overview

- A silicone rubber mold is made in a reversed shape of the master model using silicone rubber material.

- Liquid casting material is injected into the silicone rubber mold in a vacuum environment.

- Vacuum casting materials are cured and then taken out of the silicone rubber mold, and finally, made into finish products.

♦ Characteristics

- Generally suitable for molding a small amounts (10-20 lots).

- This method would be the best especially for experimental designs in the developmental process when quick delivery is required because the design might need to be modified. This can be easily done by modifying the shape of the master model.

- Various types of casting materials often can be combined in a single mold.

- Simultaneous multi-color casting is made possible by our unique method.

♦ Materials

ABS like (urethane based), PP like (urethane based), Acrylic like (epoxy based) and elastomer, etc.

In addition, toning, GF blending, and blending of light-diffusing agents are available. The hardness of the elastomer is adjustable.

Decoration process (Secondary process)

♦ Decoration process details

- A combination of decoration methods is available for painting, aluminum vapor deposition plating, non-conductive vapor deposition plating, and resin chrome plating.

- We also offer inkjet, laser peeling and more.

♦ Characteristics

- In-house toning will be implemented according to the color sample.

- Upon your request, painting service can be offered after gaining approval for the toned test pieces.

- High-precision masking using a cutting machine.

- Crack-free painting on the polycarbonate resin.

- We will respond to a quick delivery even from one piece.

♦ Painting variations

Solid color, metallic, clear, gradient color, etc. We also provide composite decorations including painting and masking on aluminum evaporation.

Simple injection molding (aluminum mold)

There are considerable benefits at the time of transition from prototype to mass production in medium amount (about several thousand pieces)

♦ Characteristics

- Aluminum mold makes it possible to shorten the delivery time and reduce the cost.

- Design can be easily modified and quick delivery is available.

- This is the most suitable method for injection molding in the production of a wide variety of small to medium quantities, where many design changes are expected.

- In case of transfer from prototype to mass production, we will produce aluminum mold based on 3D data used for prototype production. Therefore, it is possible to transfer to mass production with the shortest delivery time without the need for re-arrangement by the customer.

- Materials for injection can be specified upon request.

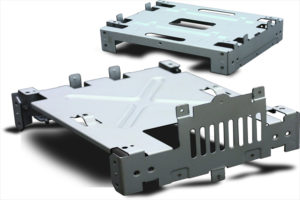

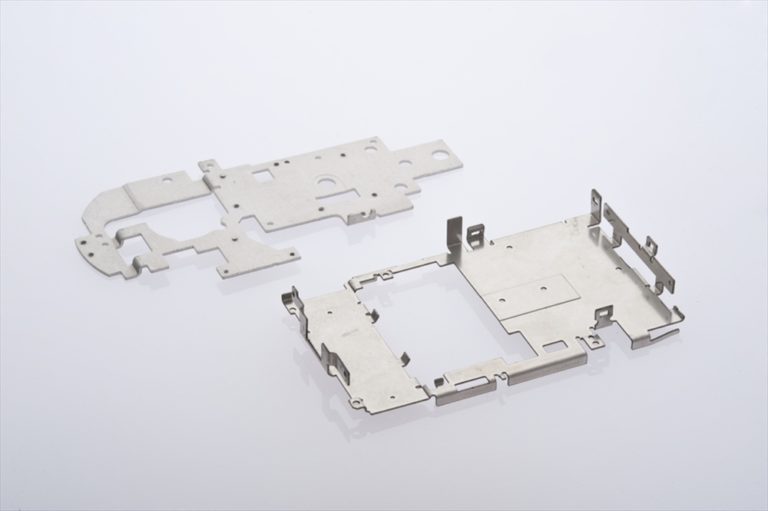

Lathe processing and sheet metal processing

♦ Characteristics

- Lathe processing and combined lathe materials processing of resin and ferrous/non-ferrous metal materials are available.

- For sheet metal processing, we correspond to laser processing, press brake, NC turret punch press, welding, caulking etc.

- Please contact us for further information.

Dimensional measurement

- Manual coordinate measuring machine, surface roughness measuring machine, and various other measuring instruments are available in our company.

- We also offer measurement services based on drawings and examination of specific parts of products.

- Actual parts are measured and then converted into 3D data and drawings in association with our Design and Development department.

♦Examples

- Applied for retrofit

- Actual parts to be converted into 3D data or drawings to manufacture new products with design change.

- Requests from customers for inspection reports and process capability analysis

- Inefficient time for the inspection or no coordinate measuring machine in-house

- An examination of trial product dimensions

- Inspection of variations in product dimensions

We have received many requests regarding design and equipment. Measurement is conducted according to your requests after detailed discussions on such as measuring instruments and measurement standards to be used.