Modeling Service

What We Offer

Manufacturing unique and innovative designs by your designers often requires drawing of built-in mechanisms and housing.

Well–versed designers in our Design and Development Department can work directly with your designers to make proposals on prototype production as well as mass production.

Why Choose Us

Designing Capability

We will design based on sketching, drawing or concept. We convert your ideas to CAD data to utilize its virtual images and designs and to support you in mechanism designing.

One-Stop Manufacturing

We also offer a one-stop service from model design to prototype production.

Industries We Serve

Past Works

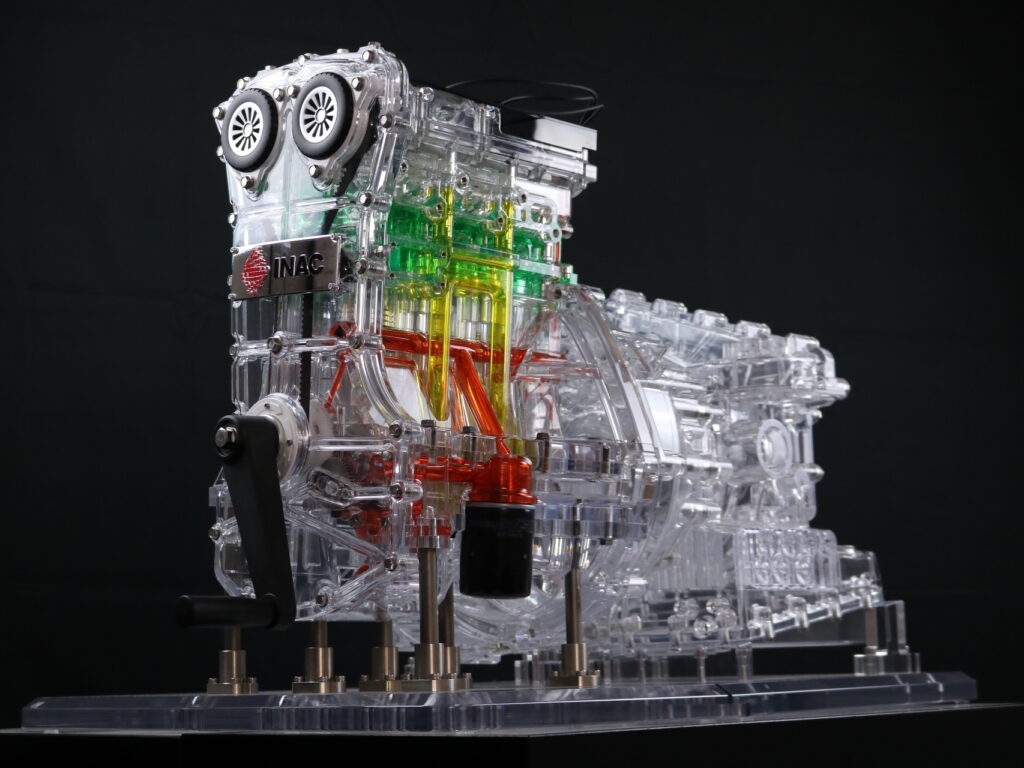

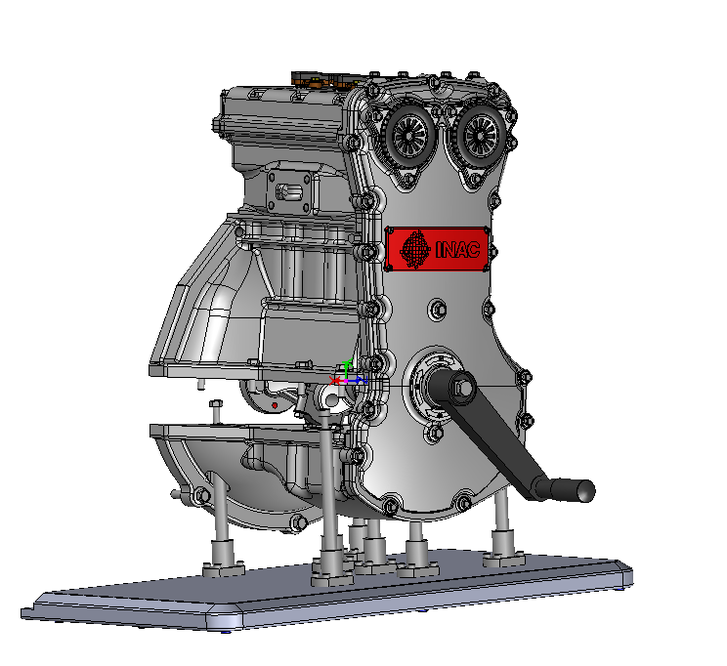

Engine Visualization

An Internal visualization model of engines and transmissions used in automobiles/industrial machinery.

The model can be used for observing oil poured inside the transmission. Using simulations, we can perform analysis that is normally difficult such as dropping in oil under its own weight and observing the generation of bubbles.

We also design electrical equipment in-house that can do things such as making a light shine when turning the engine handle, or connecting to speakers to play audio.

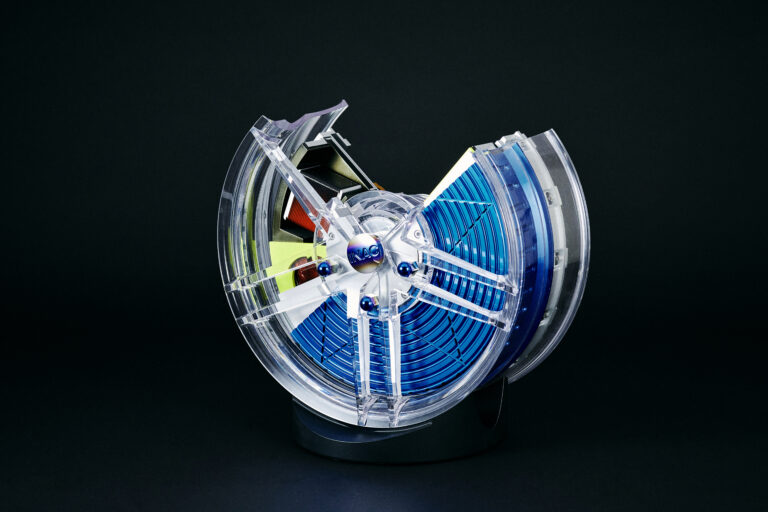

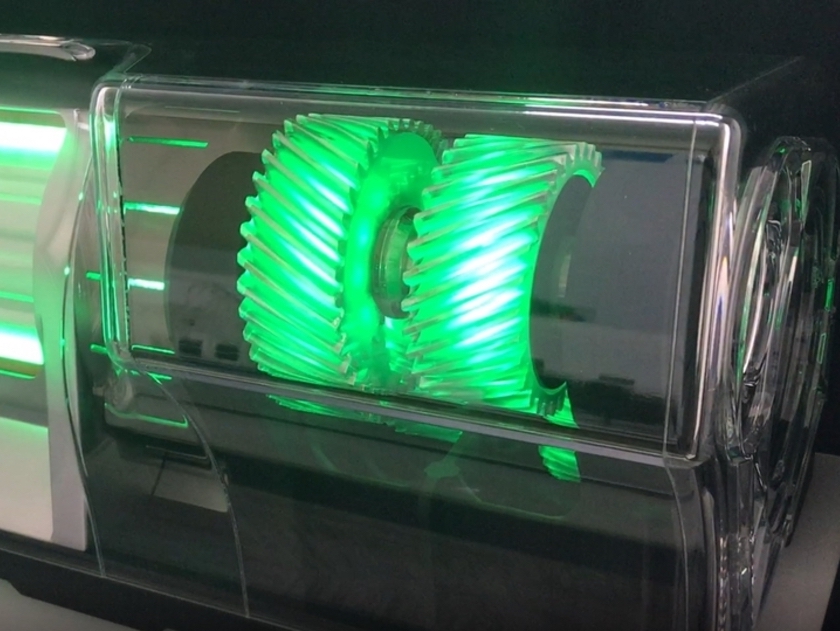

e-Axle Electric Sample

This is a mock-up sample of an e-Axle’s internal components with emphasis on movement and design. The loader and gears rotate at three different speeds, and the electrical components are designed to change the color of light emitted according to the rotation speed. This sample is sure to catch the attention of visitors at an exhibition.

What is an “e-AXle”?

The e-AXle is a unit for electric vehicles that combines an electric motor, power electronics, and gearbox. This reduces electric drive complexity while maintaining compactness and light weight.

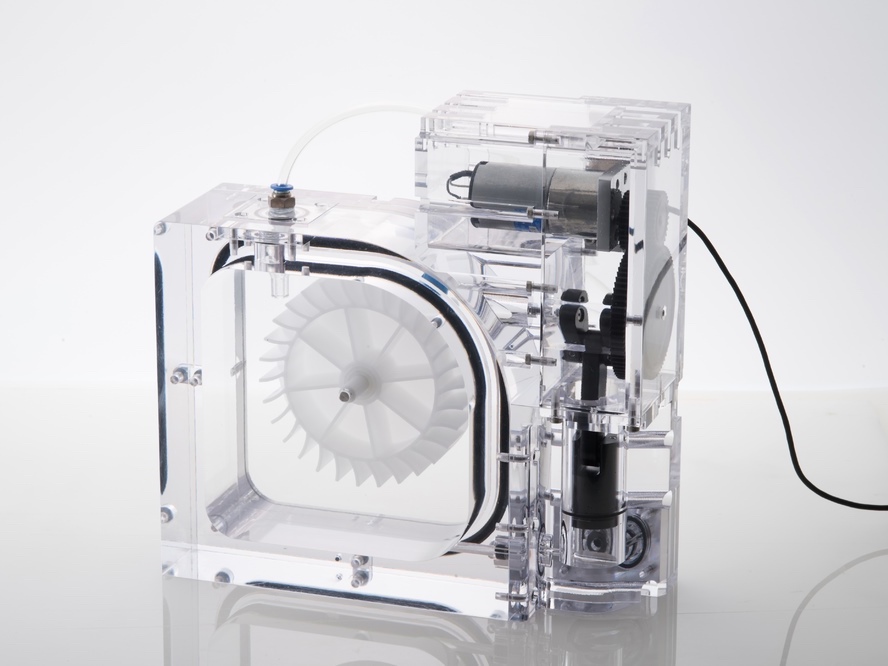

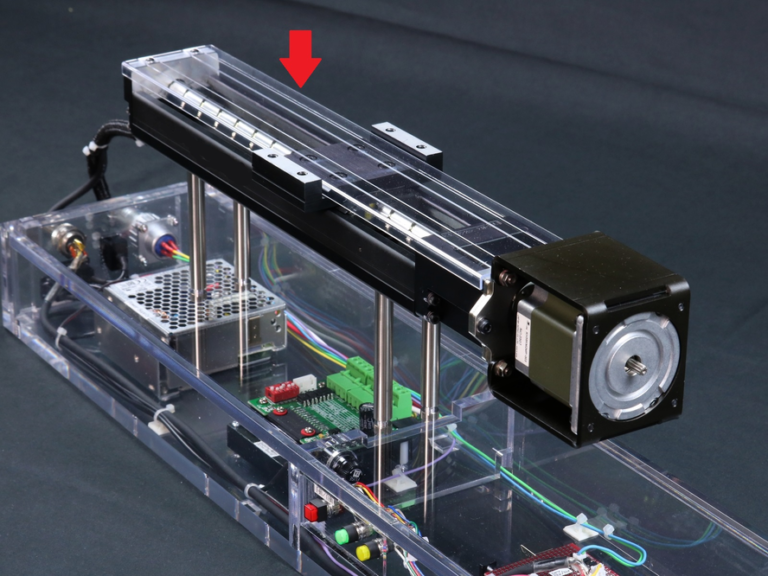

Cross Sectional Model

A significant reduction in weight can be achieved by manufacturing “cut models” through resin processing and decorative treatments instead of conventional ferrous and nonferrous metals.

The reduction in weight lowers transportation costs and reduces risks in handling.

FAQs

Yes, our designers will create the 3D models for you.

Yes, please do contact us for electrical designs. We will support you in creating more attractive products such as display samples with LED lights.

We can create all sorts of designs even from rough sketch concepts. Please contact us for mechanical designs, concept designs, electrical designs, or any other problems you would like to solve.

Yes, we can make such accommodations. For parts with matings, modeling is performed with clearances taken into consideration. We check the matings before shipment to ensure a high quality.

Get In Touch!

If you have something you want to make, please contact us. Even a rough idea is OK.

We will give shape to your idea and deliver it to you. Please feel free to contact us.