CROSS-SECTIONAL MODELS

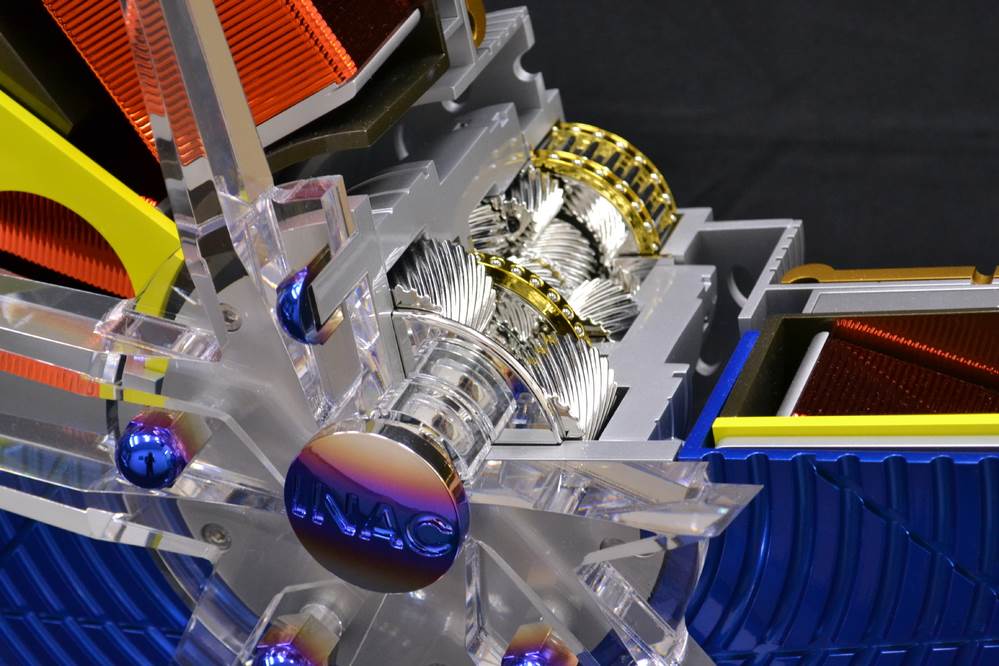

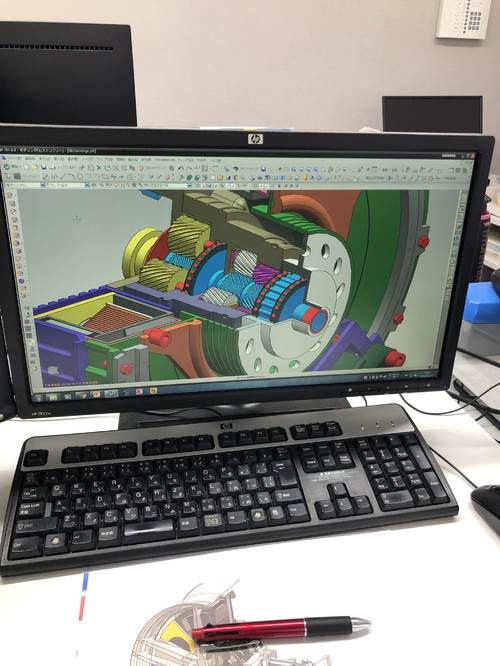

LIGHT CUT MODEL STYLE 17 INCH WHEEL MOTOR Mechanism design

CROSS-SECTIONAL MODELS

We offer extremely lightweight cross-sectional models.

Cross sectional “cut models” are made of ferrous and non-ferrous metals. Achieved with expert craftsmanship using resin and decorative processing.

Advantages:

Compared with ferrous or non-ferrous metal, it can be significantly reduced in weight.

・ Approximately 1/7 of iron

・ About 1/2 made of aluminum

Benefits of weight reduction

・ Improved flexibility in exhibition methods

・ Reduction of transportation cost

・ Reduction of handling risk

Further weight reduction

-It is possible to further reduce the weight by hollowing out the part that cannot be seen in the structure.

Design

・ Expose the mechanism by designing which parts are transparent and partially transparent.

-Incorporate LED lighting inside the parts to make them stand out.

・ Half evaporation plating and internal lighting are combined to show the surface design and internal structure at the same time by turning the lighting on and off.

Maintenance Free

・ Because no iron or non-metal is used, no rust is generated and the appearance can be maintained.

Material used

Polycarbonate (transparent, black)

Transparent Stereolithography Material (TSR-829)

Use method

Cutting (3 axis, 5 axis processing)

3D printer (transparent stereolithography)

Polycarbonate transparent treatment

Aluminum vapor deposition plating, painting (solid, color clear, gradation, etc.)

Titanium heat gradation decoration

Please feel free to contact us.

Adequate support will be provided by our experienced designers until prototype completion.