INAC US’s Tech Strength Series 01

3D Transparent Prototyping

A special section introducing our one-of-a-kind technology

The theme of the first feature is “Transparently Charming”

We offer clear transparent prototypes.

Products that have undergone our transparency treatment have a high level of transparency and can replace acrylic resin.

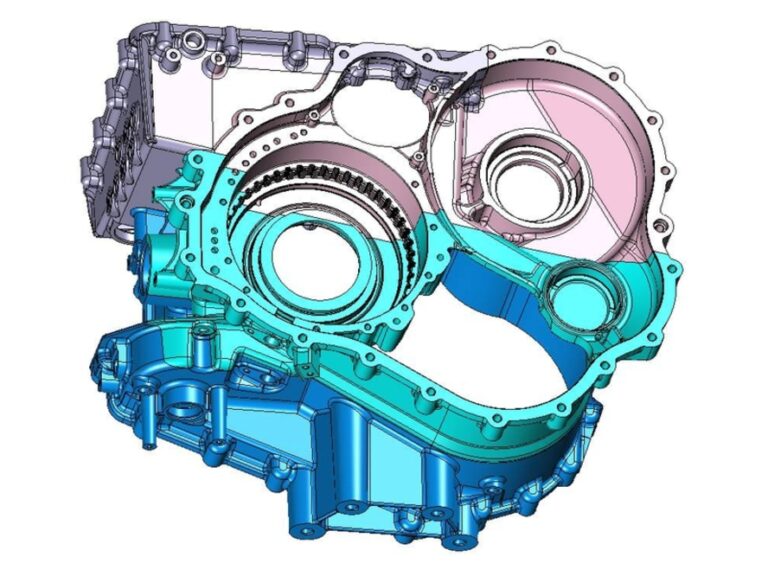

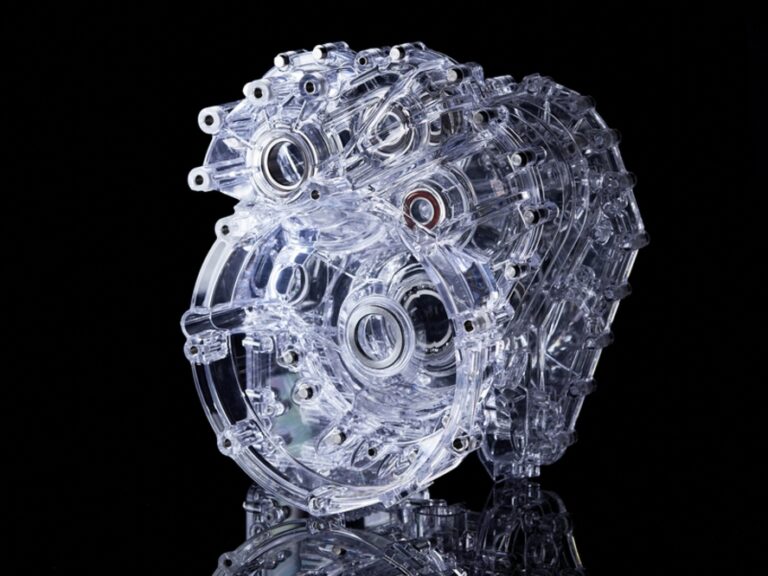

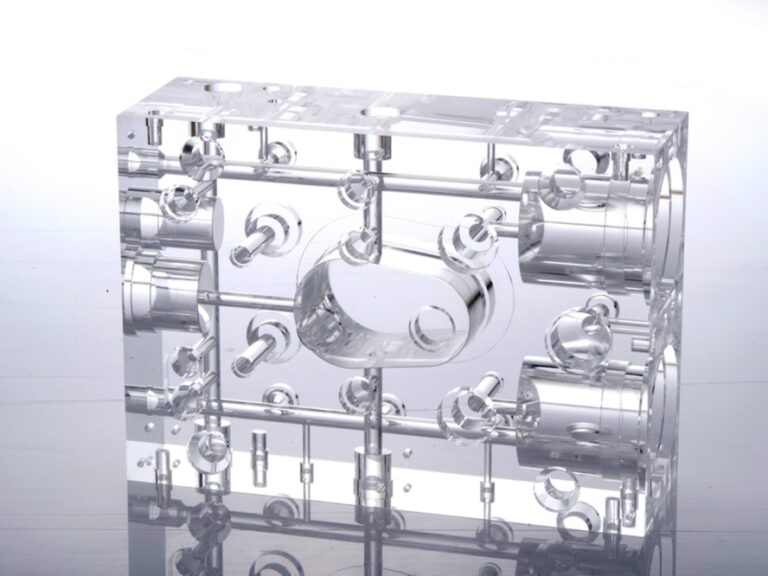

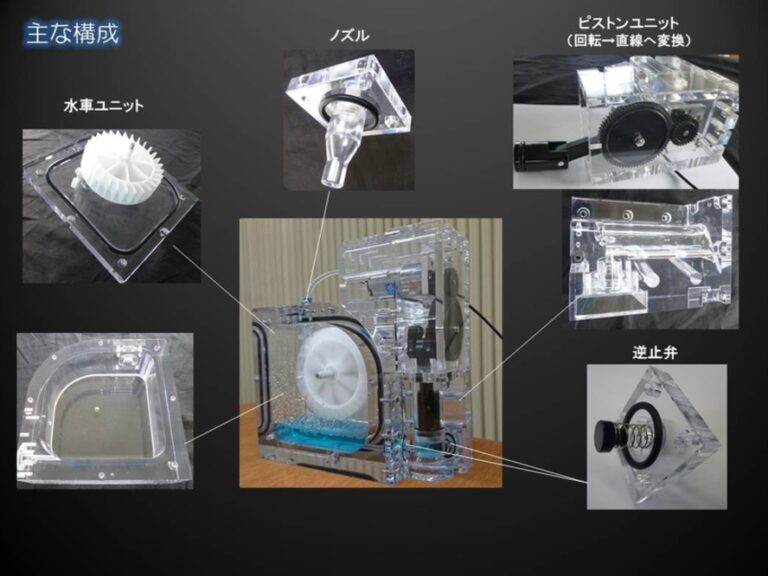

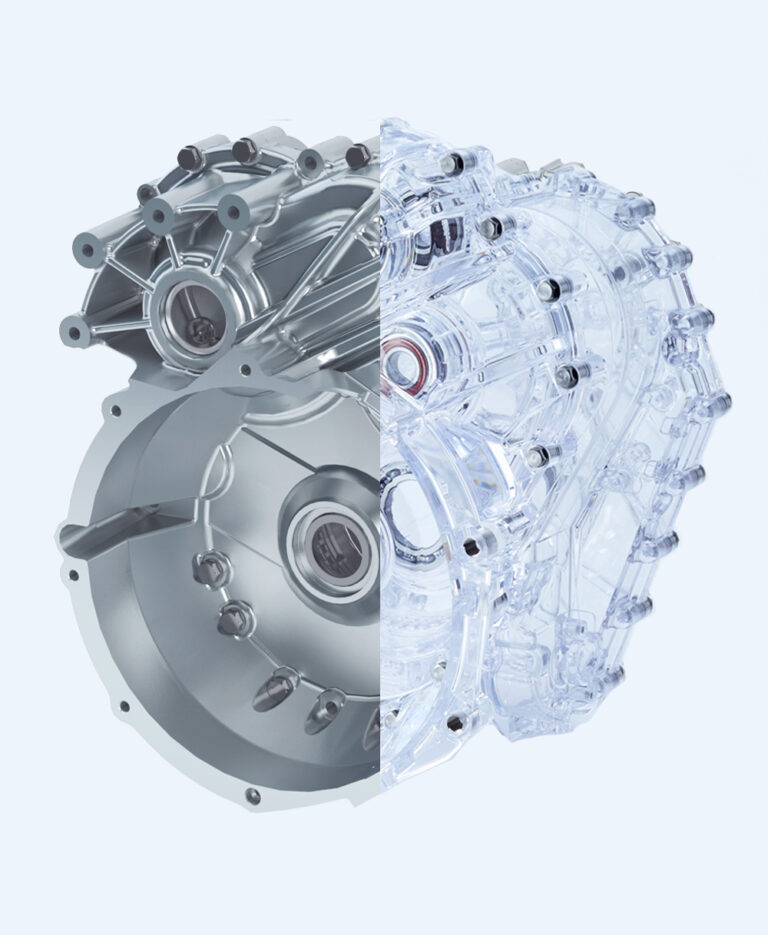

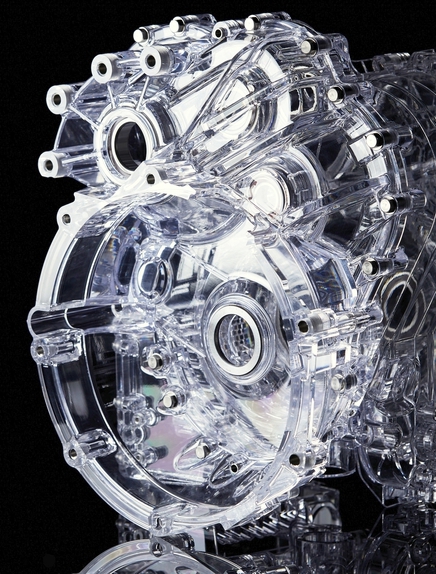

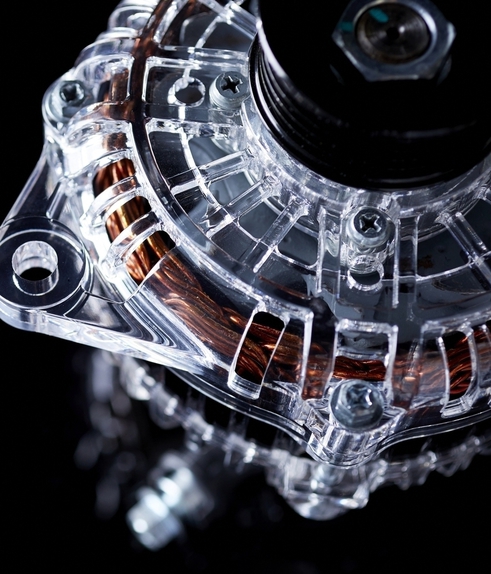

Polycarbonate transmission "internal visualization" model

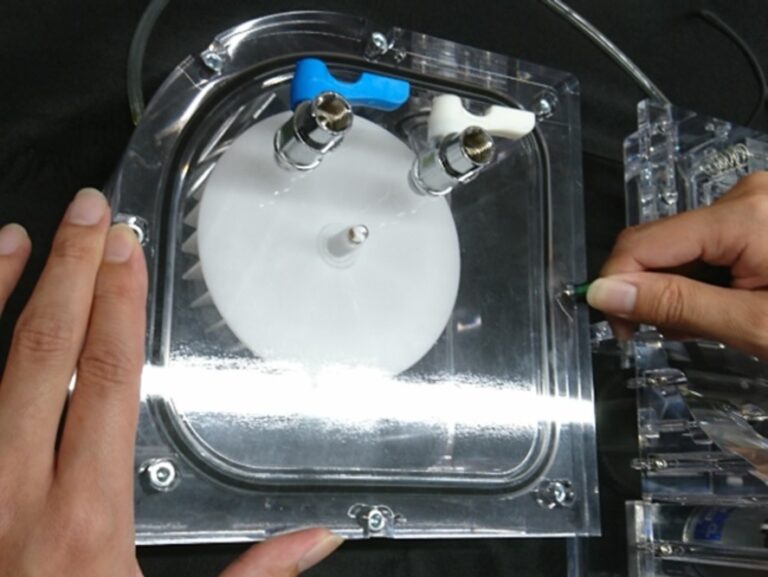

The products that we manufacture can actually be filled with oil for internal visualization.

The material is our proprietary transparency-treated polycarbonate.

We create the models using a unique reinforcement process to be able to withstand pressures.

You get an internal view to observe all sorts of mechanical components of a transmission.

"High transparency enables a wide variety of applications and versatility"

Supports a wide variety of applications

Excellent workability and impact resistance 50 times greater than acrylic!

The strongest impact resistance among transparent resins used for motorcycle helmets, light covers for vehicles such as automobiles, and windshields for fighter aircraft and the like!

We cut and machine the polycarbonate and then we process the complex shapes into individual parts. Each part is assembled by welding using a solvent mixed in-house.

The process is completed by adding bolts to areas that require additional strength.

In addition to flow analysis and visualization of the internal operation of structural components, our products are used for a variety of other applications, including educational models for structural explanations and exhibits.

High transparency + High cost performance

Our products have a high transparency equivalent to glass!

Polycarbonate resin becomes cloudy and opaque when cut. Our proprietary transparency treatment can restore the original transparency of the material.

Transparency can also be achieved by a polishing process that takes an enormous amount of time and effort. Our transparency method on the other hand, achieves a high cost performance that results in a high transparency in a short period of time.

High-transparency prototypes are used in many fields

- Verification of the operation of internal mechanisms such as automobile engines and auxiliary equipment, among others.

- Samples for the exhibition and promotion of various products such as automobiles, medical care, toys, and more.

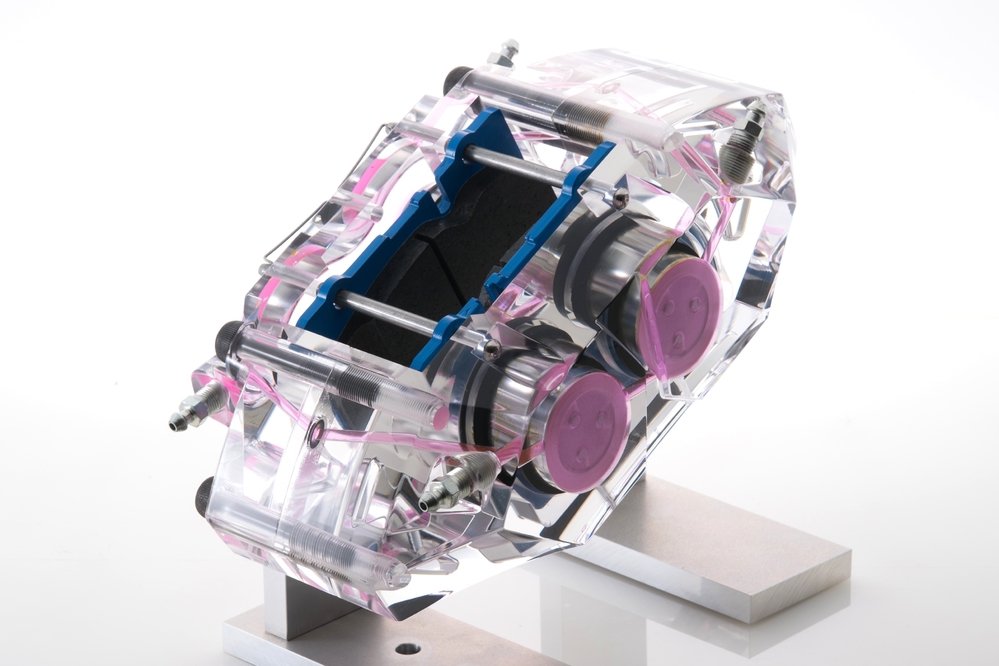

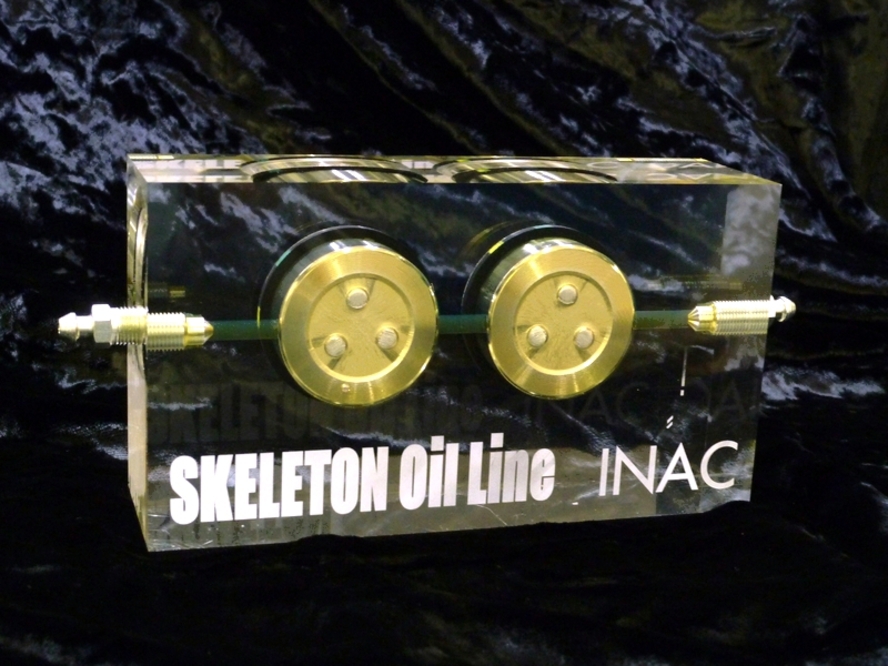

- Internal flow analysis by pouring a fluid such as oil or gas.

- Models to explain or provide education on the operation of internal structures and components.

[Example Use Cases]

Ex. 1 Quality Control!: Improved casting defect yield

A transparent internal visualization model of a mold was made and liquid was poured into it. A high-speed camera was used to observe the flow of molten metal and the cause of the problem was identified and the yield rate was subsequently improved.

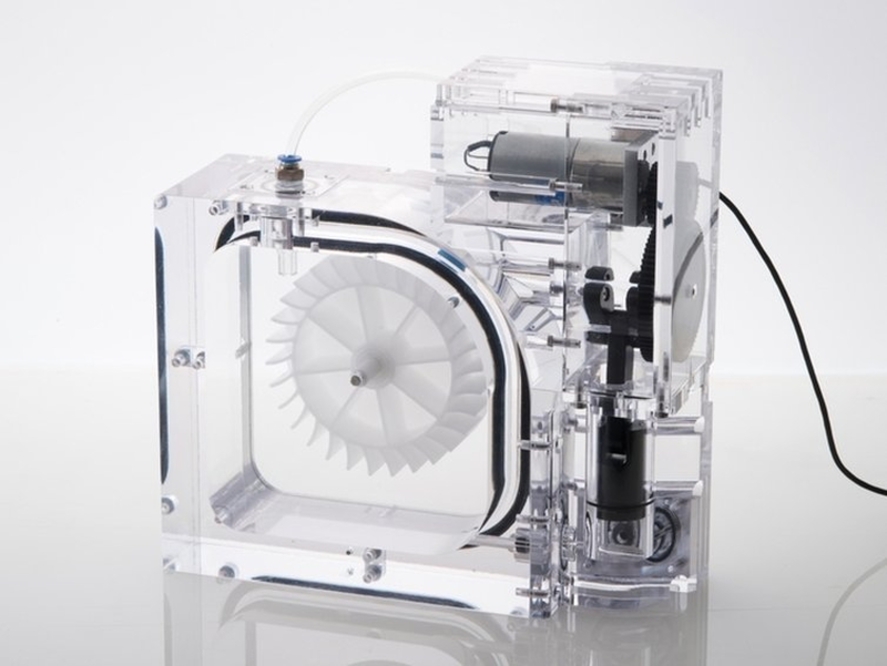

Ex. 2 Sales Tools!: Used as a tool to show off internal mechanisms to prospective customers

By assembling mechanical components into a transparent housing, the operation of the internal mechanism could be observed in real-time, making it easy for customers to understand how products worked.

Ex 3 New Product Development Validation!: Worries about unexpected interference between parts in for products in development

Transparent housing and parts were assembled on an actual device, so the clearance between the parts could be observed during operation, allowing development to proceed with confidence.

[Limited Release]

Introducing a wide variety of example use cases!!

Transmission

The pursuit of internal visualization of mechanical components

Fascinate your desire to observe

Transmission case (polycarbonate)

◆The internal mechanical components can be assembled and observed.

- Oil lubrication observation

- Verification of operation of functional components

- Educational and explanatory models

- ※Many deliveries to automobile and parts manufacturers

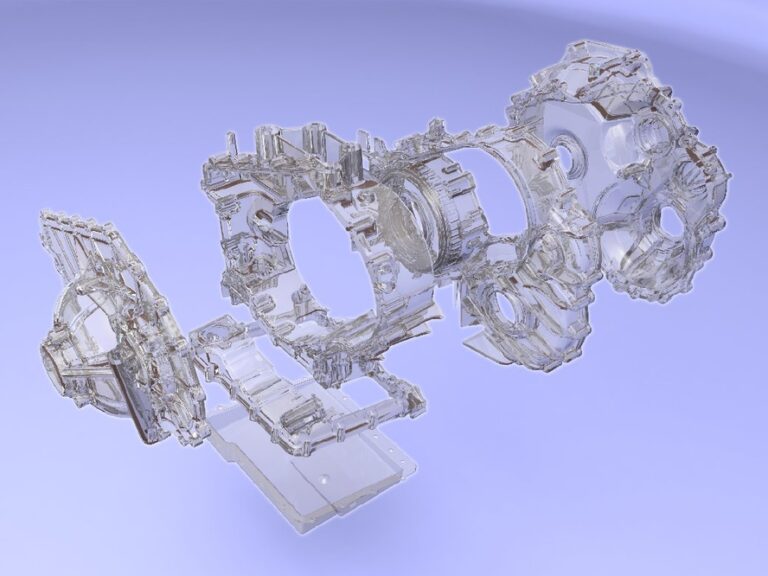

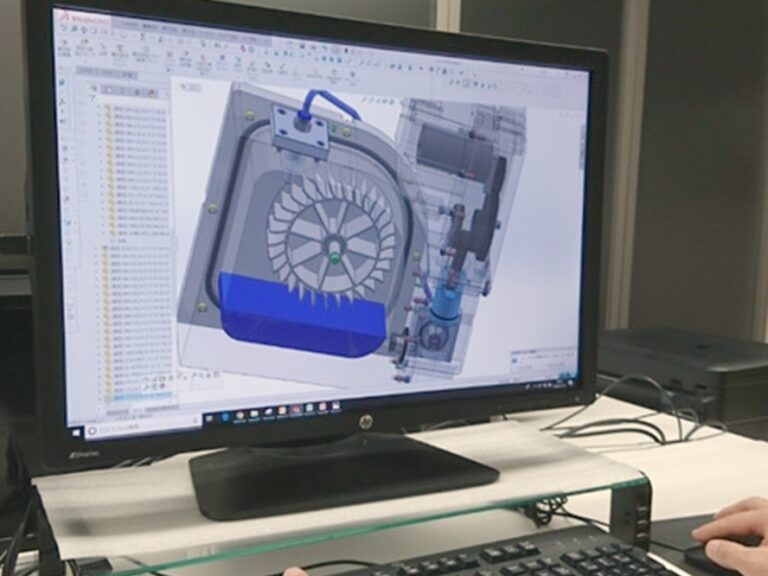

Production Process Flow

1. Meeting to work out details (we come to visit you)

Discussions are held on the outline of the product and the purposes of its use.

Explanation of processing methods.

2. Supply of 3D data

Please provide the solid data. (e.g. x_t, igs, STEP)

3. 3D data modeling (we can handle this if necessary)

Modifications such as changes to shapes in areas where strength is required, especially in areas where visualization is desired.

4. Approval of modeling for processing

Modeling is done for partitioned processing and approved by you

5. Processing start

Processing is performed at 3-axis and 5-axis machining centers.

6. Interim inspection

Verification of the workmanship of each partition processed part.

7. Finishing assembly

Finishing, transparency treatments, assembly of partitioned parts, assembly of supplied parts, helicoil inserts, coloring, etc.

8. Leak test

Checking for leakage under gravity using water.

9. Final inspection

Quality checks are performed based on the drawings provided.

Models for exhibition of mechanical components

Please use them as exhibition models!

- Transparent models attract attention.

- Complex internal mechanisms and structures are clear and easy to understand at a glance.

- Various paints, aluminum vapor deposition coating, and other composite decorations can be applied to create a cut model look.

- Lighting effects can be used to create an attractive presentation.

- Half-coatings and turning the lighting on/off from the backside can switch the presentation between the exterior and interior.

Internal visualization models for experimental evaluation

Manufacture of transparent models for experiments processed to a high degree of precision

- ※Precision: ±0.02 (depending on shape and size)

(Even higher precision is possible. Please contact us for details!) - In-house leak tests performed upon request.

- Delivered after assembly of supplied parts, purchased parts, and others.

Alternatively, delivered after confirming that the product can be assembled. - The durability of materials depends on the substances that are used, so please consult with us if you would like to discuss this further.

Transparency materials

- Polycarbonate

- Acrylic

- 3D printing (transparent optical fabrication)

- Vacuum casting

- Please consult with us about other options.

Models for the illustration of principles

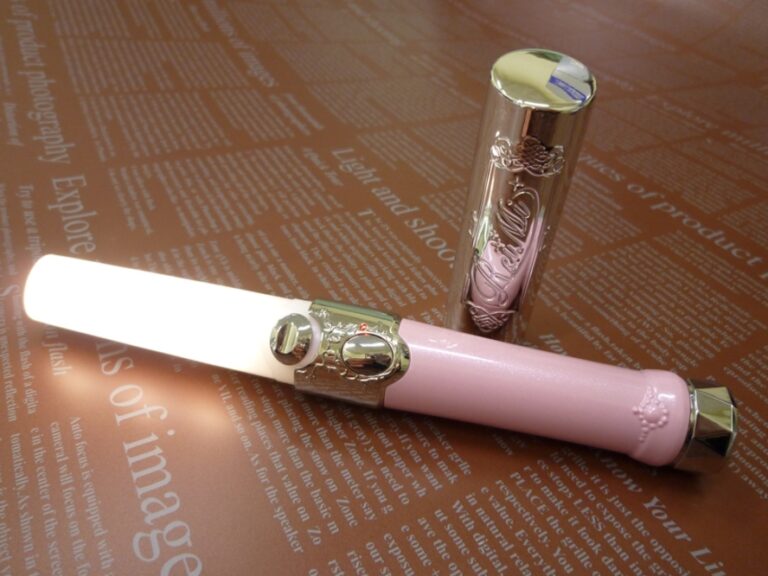

We offer a full range of services from concept and mechanism/chassis design to prototype production with ultra-short turnaround times!

- Give us a concept, and we’ll design it, even if it is a rough sketch.

- Leave it to us to provide solutions for new product development concepts, mechanism design, exhibition models, models for in-house exhibition, tools for assembly, experimental equipment and various devices.

Example use cases

We cooperated with Brother Enterprise Corporation for the design of new product concepts

The scope of our cooperation spanned from concepts to prototype production.

- Multifunctional LED light MAmoria

- Photogenic light Reimi

We are pleased to detail the resulting product with permission from Brother Enterprises Corporation.

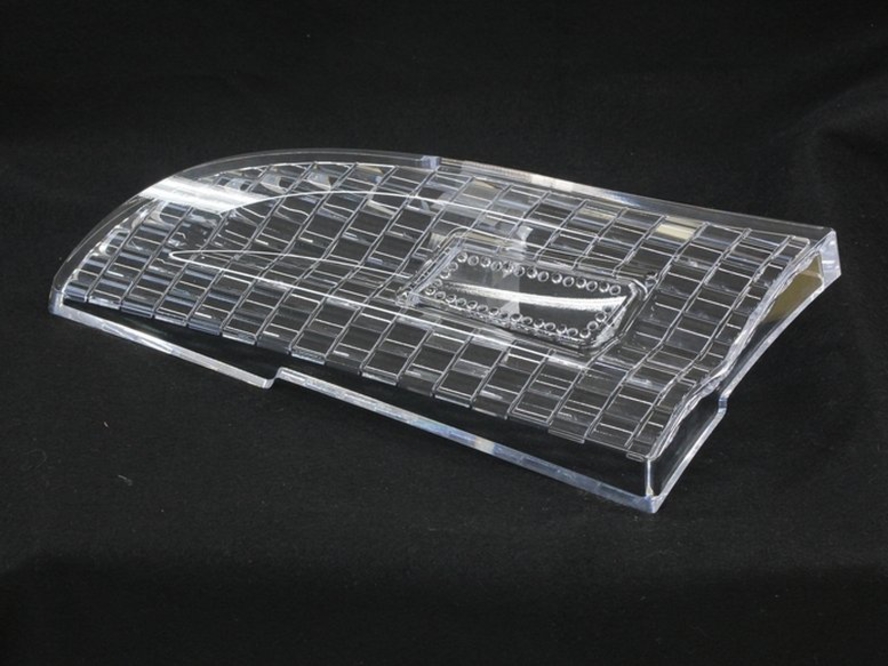

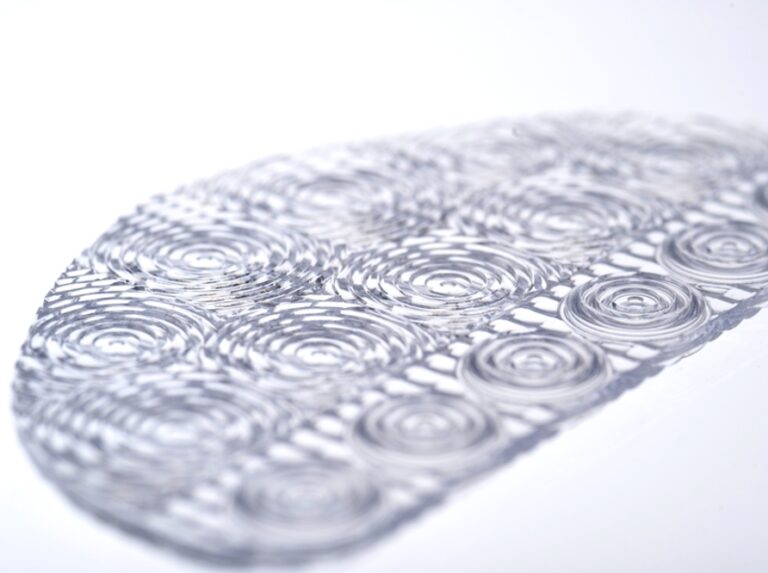

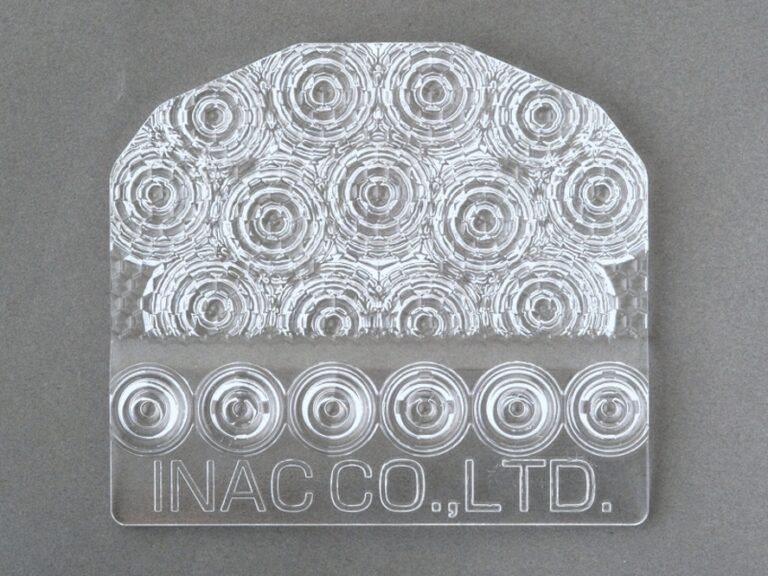

Lens cut models

Transparent finish even for microscopic lens cuts that cannot be polished

- Polycarbonate is processed to achieve a fine lens cut shape

- Unique transparency processing produces high transparency

- Lens cut for exhibition panels, among other applications

- Compatible with double-sided lens cut

Example use cases

- Covers for various types of lights for show cars (light outer covers, tail light lens cuts, covers for interior lights, etc.)

- Lens cut panels for exhibition display

- Diffusers for lighting equipment

Our sales representative will contact you as soon as possible.

* Required.

* The attachment’s total maximum size is 30 mb. Use shift or ALT key to select multiple files.

Information entered here is used for information purposes only.