Vacuum casting

Vacuum Casting

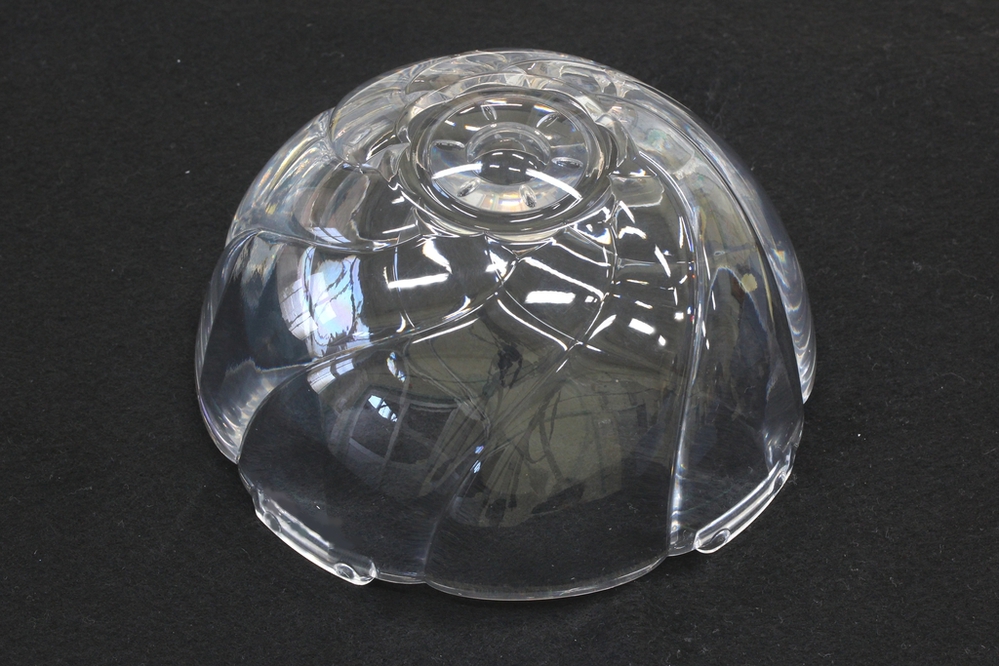

Vacuum casting option for small lot production

We will support you from the development stage.

We can handle sizes up to about the size of the front grill of a car. Most have one color, but we have the technology that allows multicolor casting such as two colors and three colors.

Vacuum casting is a method in which a master model is used to create a mold from silicone rubber, and a resin material is poured into the rubber mold to manufacture parts.Unlike a mold for injection molding, if you have a master model, you can manufacture dozens of parts in a short period of time.

In addition, since there are many types of casting materials available, you can use the same silicone rubber mold to make prototypes of various materials. Different material insert casting is also possible.

・ABS equivalent・PP equivalent・ Elastomer equivalent

・ Acrylic equivalent・ silicon・Heat resistant resin

・ flame retardant resin ★ Glass fiber can also be added

In-house, we can manufacture vacuum casting products faster by producing master models by stereolithography that can produce prototype models in a short time. Please try vacuum casting, which has high cost performance, when you need to manufacture several pieces.

Please feel free to contact us.

Adequate support will be provided by our experienced designers until prototype completion.