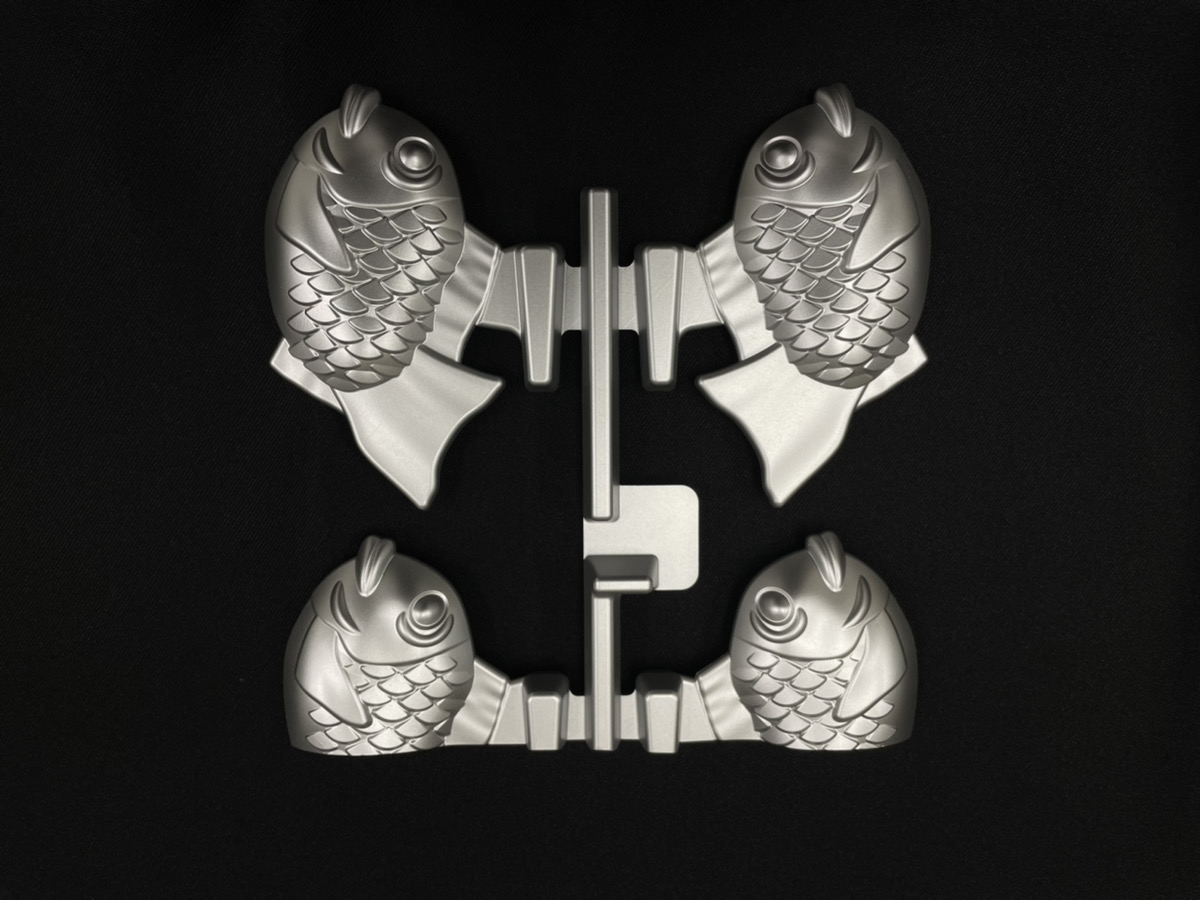

transparent mold

Transparent mold for flow analysis

High transparency acrylic machining without polishing

REPRODUCTION WITH HIGH-PRECISION DIMENSIONS WITHOUT POLISHING

It is possible to observe the internal material flow by pouring water inside. It helps you find the cause of short shot, blow-whole etc.

■ Characteristics of acrylic (PMMA)

Acrylic resin is noted for its high degree of transparency (approximately 93%) which is more transparent than glass (approximately 90%).

It is well-suited when creating models that require intricate designs, such as a monument.

◆ Our strengths

We machine acrylic products using an end mill manufactured in collaboration with a top quality blade-making firm, ensuring precise cutting.

This method eliminates the necessity for manual polishing, which can diminish dimensional accuracy, resulting in high machining precision.

In particular, transparency can be reproduced even for detailed shapes such as lens cuts, leading to the possibility of producing outstanding lens cut models.

In addition, cutting processing is performed by the dry cutting method. Therefore, the adhesion of chemical substances contained in the cutting fluid can be minimized.

Please feel free to contact us.

Adequate support will be provided by our experienced designers until prototype completion.blowhole