3D Printed CLEAR CAR

3D Printed Car Model

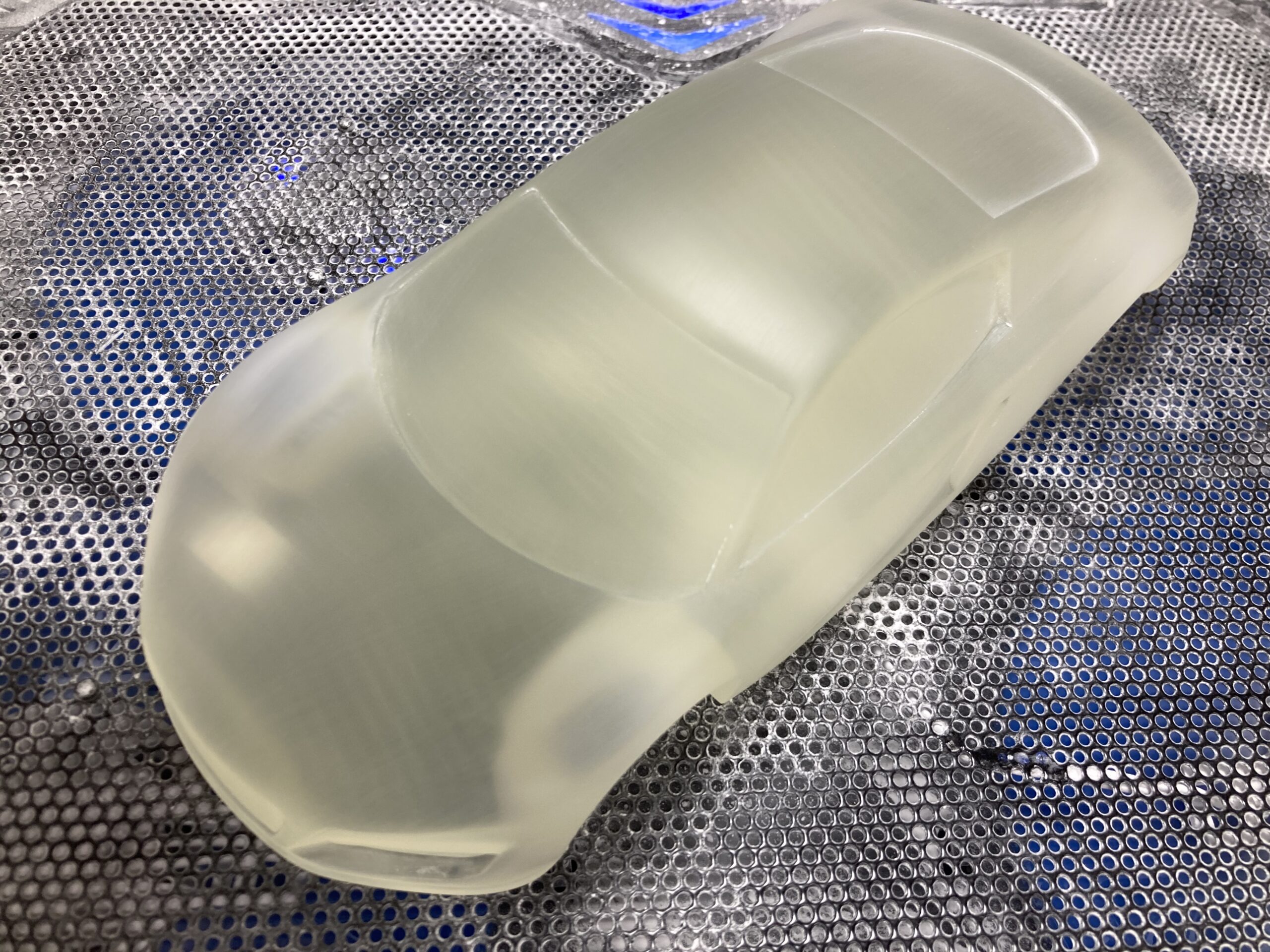

1/10 Scale Automotive Mockup – High-Quality Transparent Model

Characteristics

An astonishingly clear transparent model has been realized by minimizing internal air bubbles as much as possible.

Thanks to 3D printing technology, we are able to offer ultra-short lead times, even for urgent requests.

If you suddenly need an additional exhibit for an in-house exhibition, event, or presentation, please feel free to contact us.

Production Process

① Detailed Consultation

We begin with a detailed discussion based on your intended use and specifications.

Meetings can be conducted either in person at your site or via online tools such as Zoom.

Depending on your requirements, we can also provide sample parts and conduct basic compatibility checks for chemicals or fluids used in your application.

② Submission of 3D Data

You provide us with your 3D CAD data for production.

③ Creation of 3D Printing Programs (Our Core Know-How)

We carefully plan how the product will be built layer by layer.

By combining various 3D printing parameters and conditions, we create a dedicated printing program using specialized software to achieve optimal results.

④ 3D Printing

UV laser light is selectively applied to the resin, and the shape is formed through repeated layering.

The minimum layer thickness is 0.05 mm, although 0.1–0.15 mm is commonly used.

Finer layers result in a smoother surface but require longer printing time, so achieving the right balance is essential.

⑤ Completion of 3D Printing

Support structures are added during printing to maintain the shape.

After printing, the part is washed and unnecessary support structures are carefully removed.

⑥ Surface Finishing

Layer lines are removed by hand finishing to create a smooth surface.

If transparency is not required, the product can be delivered at this stage.

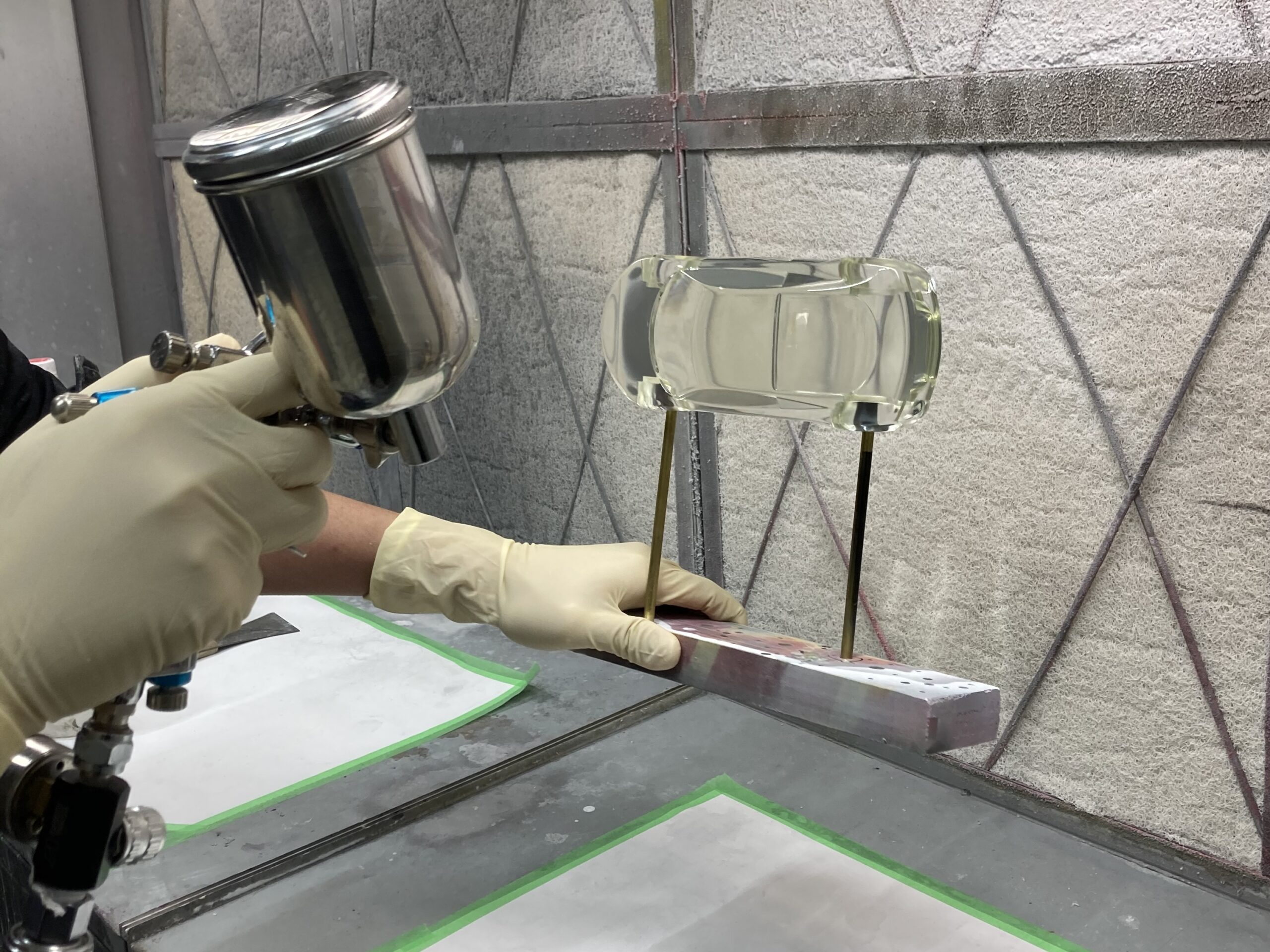

⑦ Clear Finish (Final Product)

A clear coating is applied to achieve a clean, highly transparent final appearance, completing the process.

Material: TSR 829 (Moisture-resistant highly transparent materials)

Size: 1.18 × 2.36 × 0.59 inches (diameter:φ0.0094 inches)

Please feel free to contact us.

Adequate support will be provided by our experienced designers until prototype completion.