ABS Prototyping Service

Overview of ABS

ABS Material Properties

| Density | 1.04 g/cm³ |

|---|---|

| Elongation at Break | 20-30% (approximately 25% strain) |

| Tensile Strength (Yield) | 40-45 MPa |

| Impact Strength (Notched Izod, 73.4℉) | 15–20 kJ/m² |

| Hardness | Rockwell R100–110 (R-scale) (approximately Shore D 75–85) |

| Flexural Strength | 65–75 MPa |

| Heat Deflection Temp. (HDT @ 1.8 MPa) | 194℉ |

Note: Values may vary slightly depending on specific grades or formulations.

Benefits of ABS

High Impact Resistance: ABS can withstand significant mechanical stress, reducing the risk of cracking or deformation.

Cost-Effective: Widely available and relatively affordable, making it ideal for rapid prototyping and iterative design.

Surface Finishing Flexibility: Easy to paint, plate, and bond, allowing for diverse aesthetic finishes.

Good Dimensional Stability: Suitable for parts requiring tight tolerances and consistent geometry.

Thermal Resistance: Maintains shape and structural integrity under moderate temperatures.

INAC US’s ABS Prototyping Capability

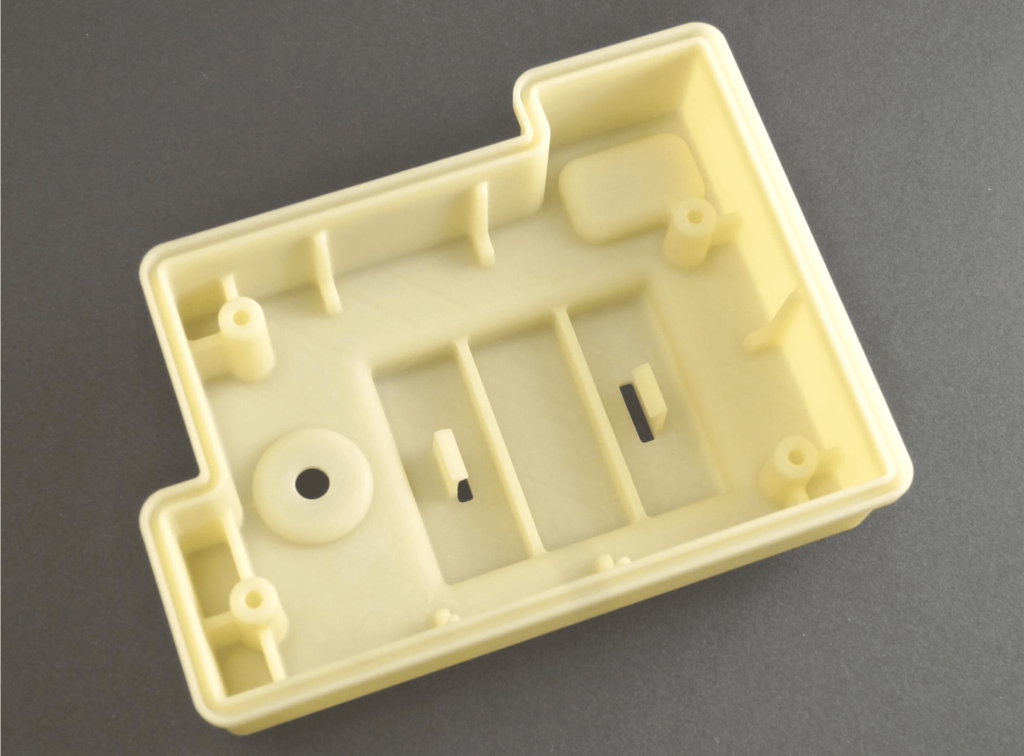

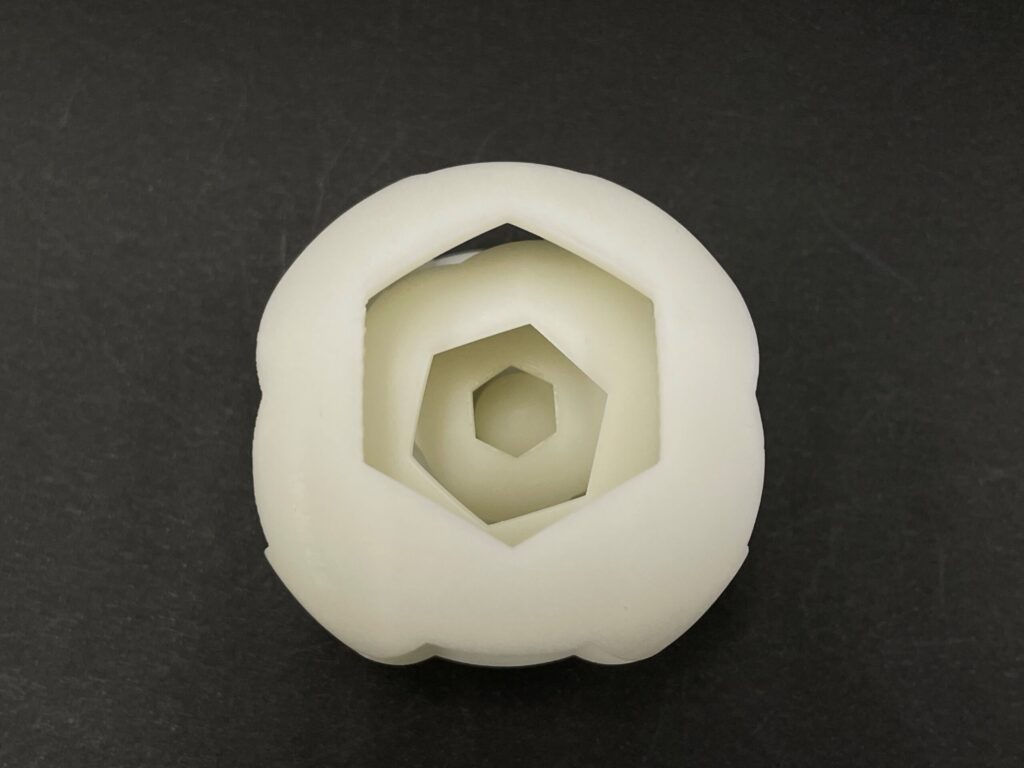

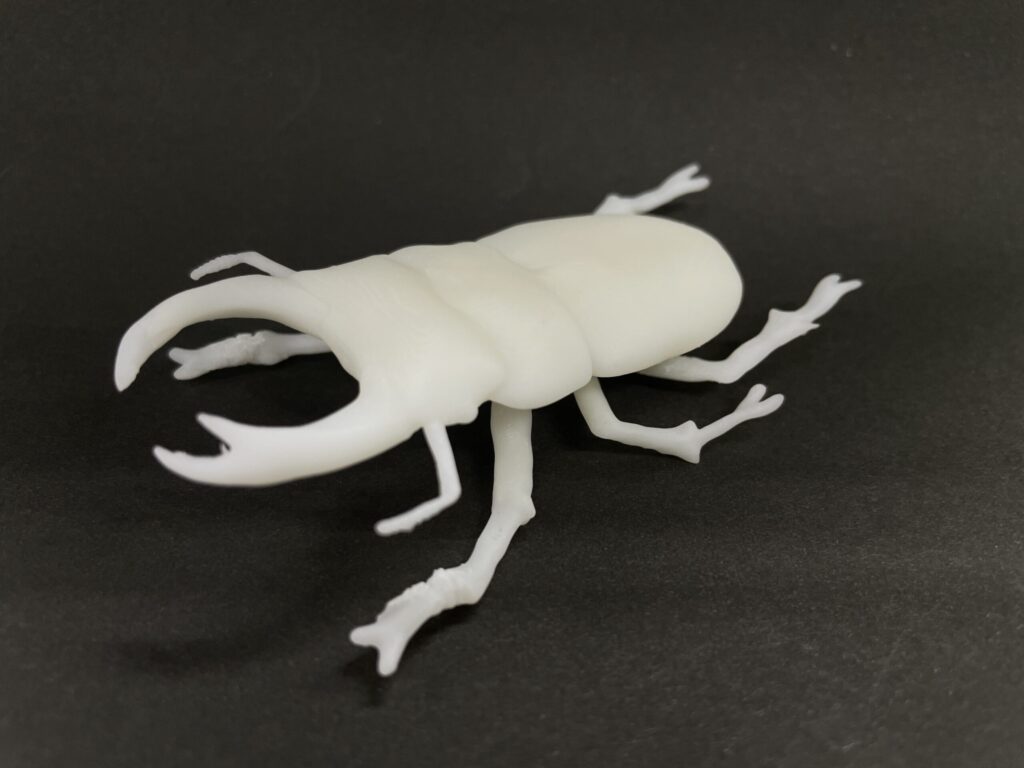

ABS Prototype Portfolio

ABS Prototyping Methods

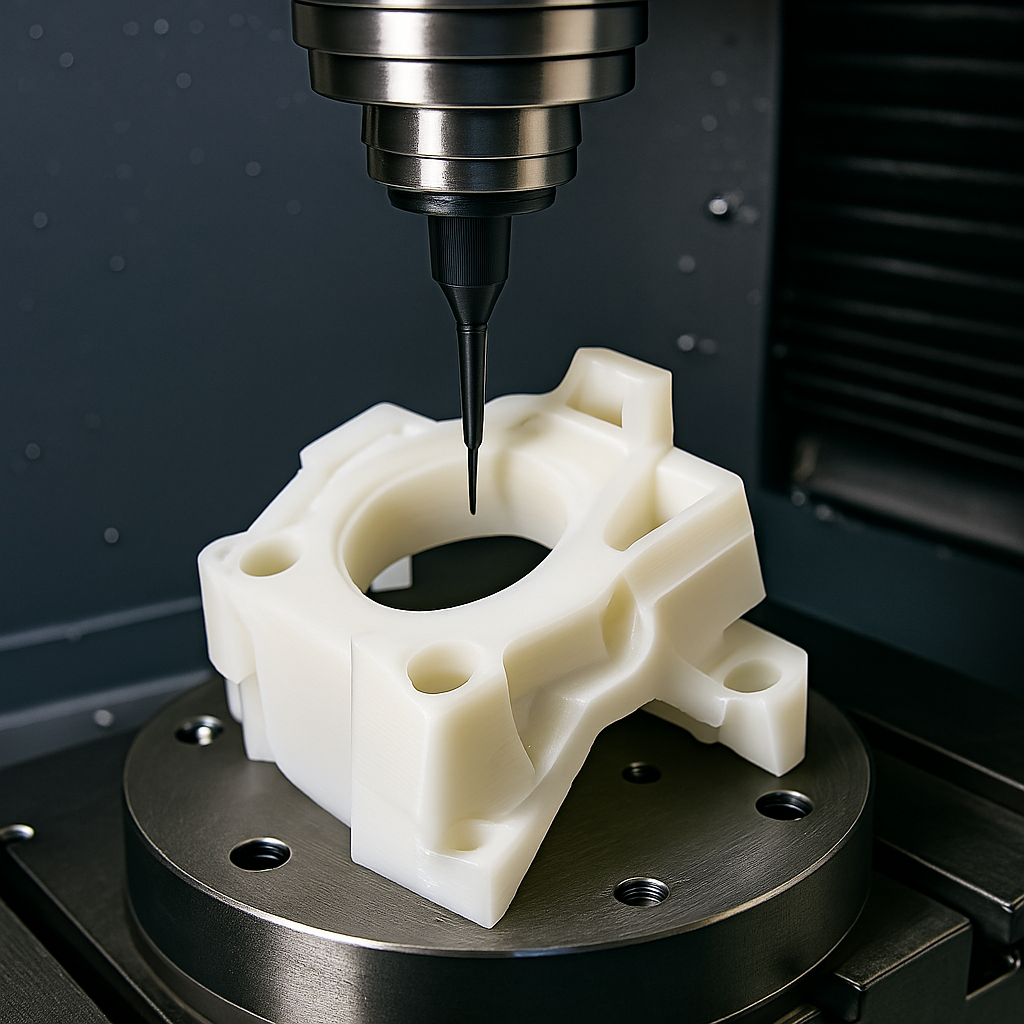

CNC Machining

High Precision: Our 5-axis machining centers enable complex ABS parts with tight tolerances.

Fast Turnaround: Automated processes and skilled technicians ensure efficient lead times.

Versatile Designs: Intricate geometries and fine details are achievable for functional testing or display models.

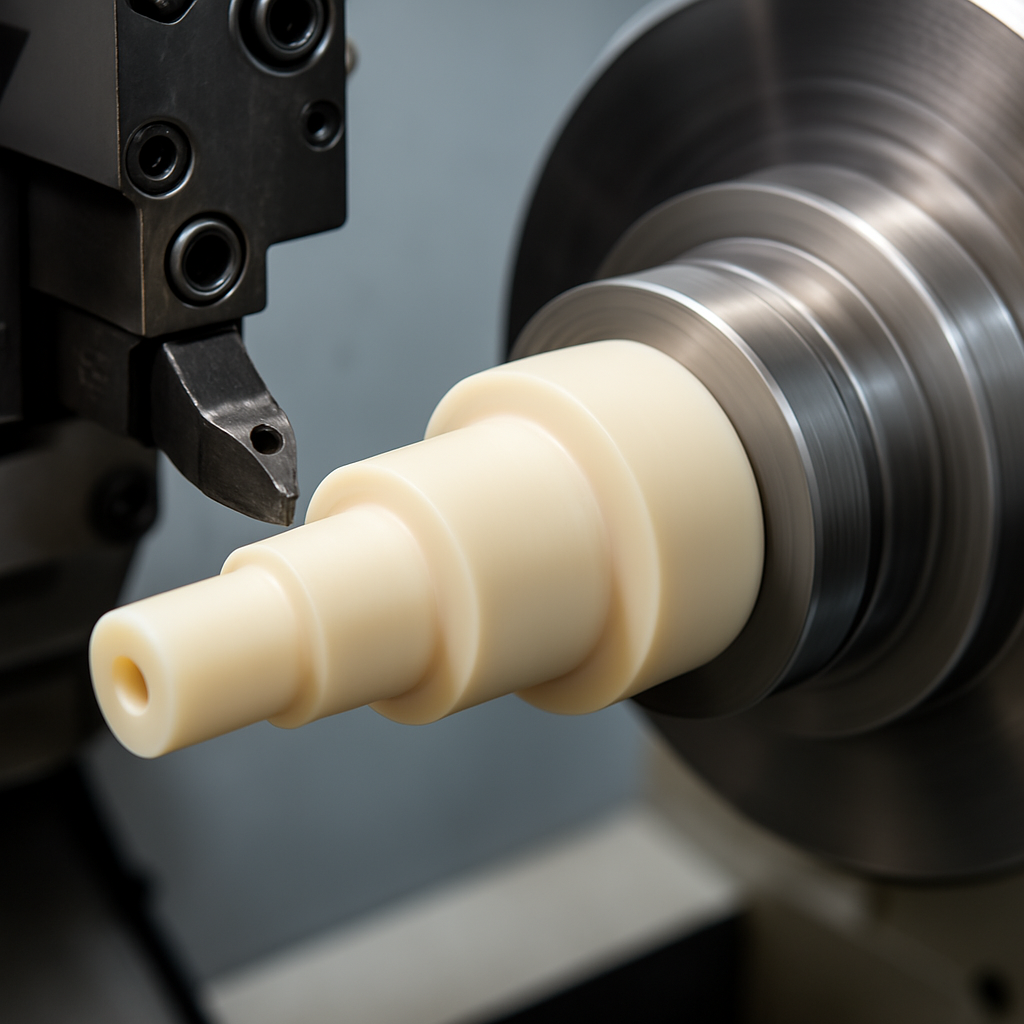

Lathe Processing

Rotational Parts: Ideal for shafts, cylindrical components, and round profiles.

Smooth Finishes: Achieve a refined surface suitable for moving parts or aesthetic purposes.

Efficient Production: Perfect for short-run or small-batch parts that need quick delivery.

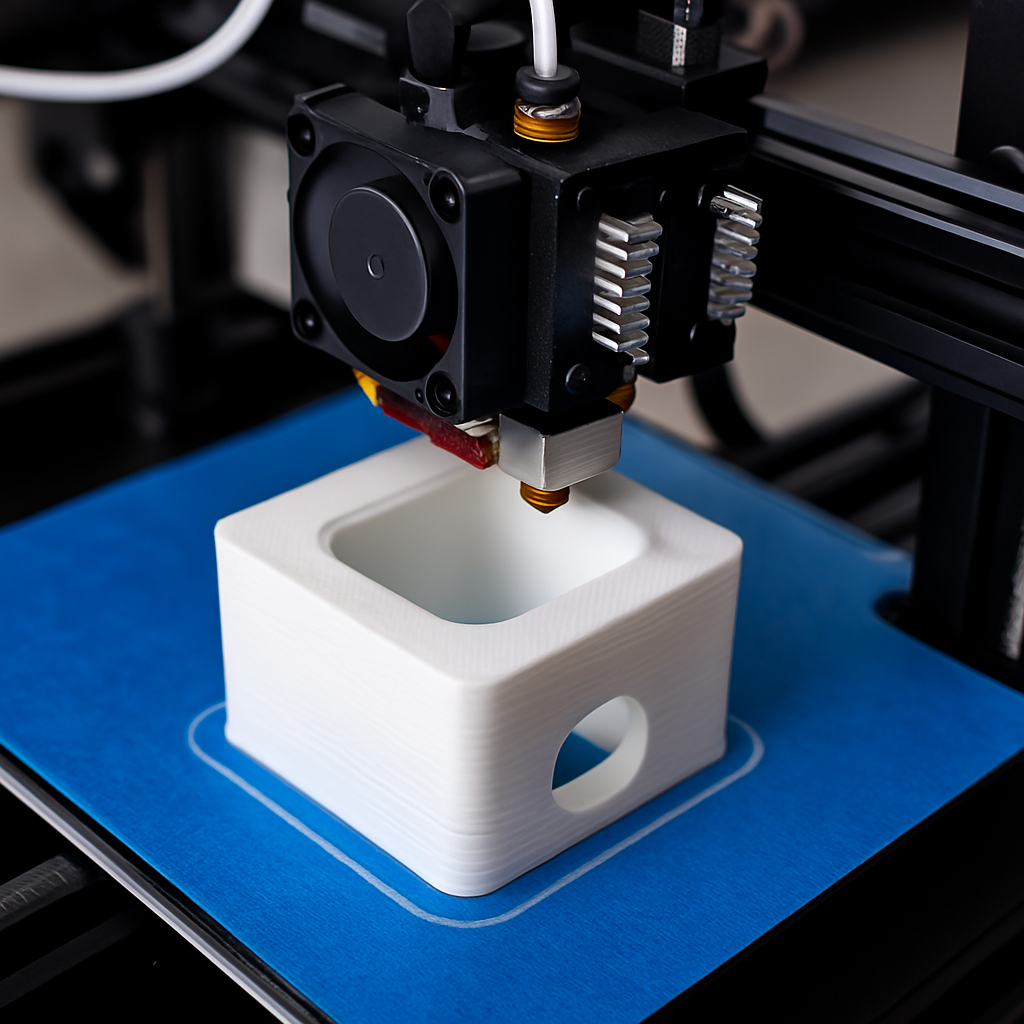

3D Printing

Rapid Prototyping: Perfect for fast design iterations and complex geometries that are challenging with traditional methods.

Less Material Waste: Additive manufacturing only uses what is needed, minimizing scrap.

Functional Models: ABS 3D prints offer good strength for testing.

FAQ about INAC US's ABS Prototyping Service

A. Our standard lead time varies depending on design complexity and finishing requirements, but we usually deliver within 5–10 business days. Rush services may be available upon request.

A. Yes. We offer custom painting, surface texturing, aluminum deposition, and laser exfoliation options to meet your aesthetic and branding needs.

A. Absolutely. Our advanced CNC machining and lathe processing capabilities enable us to create robust, functional prototypes suitable for mechanical and operational testing.

A. We use a range of coordinate measuring machines (CMM) and other inspection tools to verify precise dimensions and ensure all prototypes conform to your specifications.

A. We accommodate both. Whether you need a single prototype or a large-volume production run, our facilities can scale to suit your requirements.The upper limit is often a few hundred pieces.

Guide to ABS Prototyping

What Is ABS(Acrylonitrile Butadiene Styrene) Material?

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic renowned for its excellent impact resistance, dimensional stability, and machinability. Its ease of shaping and finishing makes it a popular choice for creating prototypes that require both functional testing and visual appeal. ABS can be utilized in a broad range of industries—from automotive and consumer electronics to household appliances.

Grades of ABS Material

| Property | Value |

|---|---|

| Density | 1.04 g/cm³ |

| Elongation at Break | 20-30% (approximately 25% strain) |

| Tensile Strength (Yield) | 40-45 MPa |

| Impact Strength (Notched Izod, 73.4℉) | 15–20 kJ/m² |

| Hardness | Rockwell R100–110 (R-scale) (approximately Shore D 75–85) |

| Flexural Strength | 65–75 MPa |

| Heat Deflection Temp. (HDT @ 1.8 MPa) | 194℉ |

Applications of ABS Prototypes

Consumer Electronics

ABS prototypes provide a sturdy yet visually appealing option for consumer electronics. They allow thorough testing of product housings and enclosures while maintaining a realistic final product appearance.

Automotive

ABS prototypes are well-suited for both interior and exterior automotive components, thanks to their impact resistance and thermal stability. They help validate dashboards, trim pieces, and under-hood parts before mass production.

Medical and Healthcare

ABS prototypes support ergonomic design and device testing in medical applications. Their strength and surface finish enable realistic evaluations of user interaction and compliance with safety standards.

Comparing ABS to Other Engineering Plastics

| Plastic | Description |

|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | – Good Impact Strength: The butadiene content provides toughness and shock resistance. – Easy Processing: Commonly injection molded; also suitable for 3D printing (FDM). – Balanced Properties: Offers moderate strength, decent chemical resistance, and good dimensional stability. |

| PC(Polycarbonate) | – High Impact Resistance: Often used for safety shields, machine guards, and protective screens. – Optical Clarity: Up to 90% light transmission, though prone to scratching without hard coatings. – Heat & Flame Resistance: Can withstand elevated temperatures; available in flame-retardant grades (UL 94 V-0). – Dimensionally Stable: Retains shape under load, making it suitable for precision parts. |

| Acrylic (pmma) | – Excellent Transparency (~92% light transmission) with a glass-like appearance. – Lightweight & Weather Resistant: Resists yellowing and cracking outdoors better than polycarbonate. – Easy Fabrication: Can be thermoformed, laser-cut, or polished for display-quality finishes. |

| POM(Polyoxymethylene) | – High Stiffness & Low Friction: Excellent for gear teeth, bearings, and wear strips. – Dimensional Stability: Minimal moisture absorption, retaining tight tolerances. – Good Chemical Resistance: Withstands many solvents, fuels, and lubricants. |

| PP (Polypropylene) | – Lightweight & Affordable: One of the lowest densities among engineering plastics, making it cost-effective. – Good Chemical & Moisture Resistance: Does not absorb water readily, resists many acids and bases. – Flexible in Thin Sections: Used in living hinges. |

| Nylon | – Excellent Toughness & Wear Resistance: Ideal for moving or sliding parts. – Varied Grades: Nylon 6, 6/6, 12, etc., each offering different stiffness, moisture absorption, and temperature performance. – Good Fatigue Strength: Retains mechanical integrity under repeated stress. |

| PEEK (Polyether Ether Ketone) | – High Temperature Tolerance: Can sustain mechanical properties up to ~480°F. – Chemical & Hydrolysis Resistance: Suitable for harsh chemical environments; steam-sterilizable. – Biocompatibility: Certain grades used in medical implants. – Low Outgassing: Ideal for aerospace applications. |

| PPS(Polyphenylene Sulfide) | – High Thermal Stability: Can withstand continuous use at ~390–430°F. – Flame Retardant & Chemical Resistant: Excellent performance in corrosive and high-temperature conditions. – Good Dimensional Precision: Low coefficient of linear thermal expansion (CLTE). |

| PET(Polyethylene Terephthalate) | – Good Stiffness & Dimensional Stability: Suitable for precision mechanical parts. – Low Moisture Absorption: Minimizes swelling or warpage. – Chemical Resistance: Resists oils, solvents, and mild acids. |

| PBT(Polybutylene Terephthalate) | – Good Electrical Insulation: Ideal for connectors, switches, and other E/E parts. – Dimensional Stability: Low shrinkage, low moisture absorption, good for tight tolerances. – Chemical & Heat Resistance: Withstands automotive fluids and moderate temperatures (~302–320°F). |

If you have something you want to make, please contact us. Even a rough idea is OK. We will give shape to your idea and deliver it to you. Please feel free to contact us.