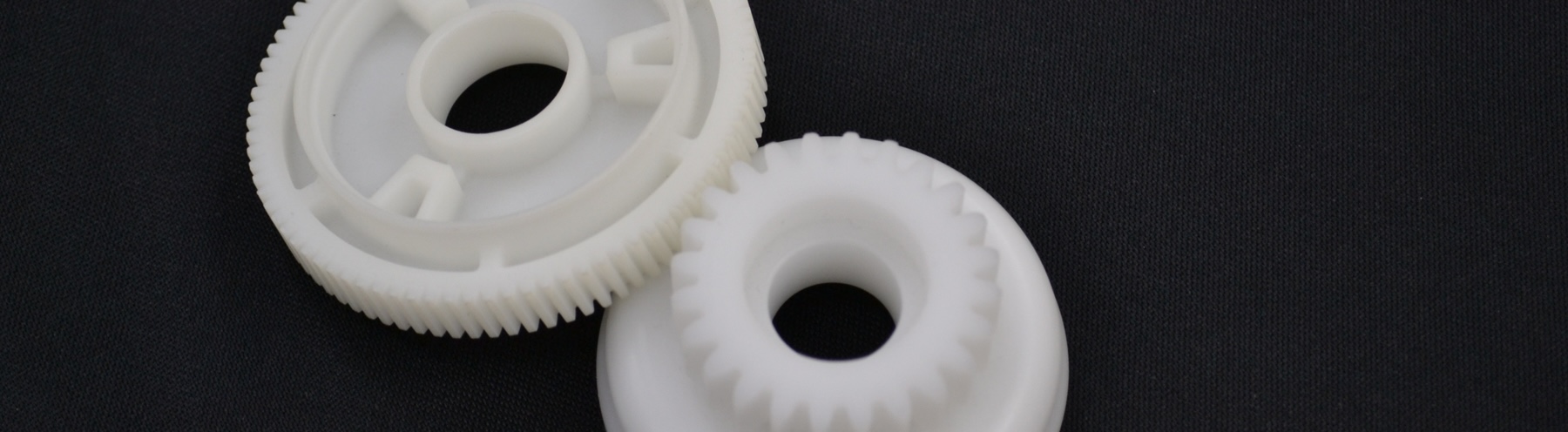

Machined POM Gear

3D Printed Car Model

High-Precision Gear Machining

In this manufacturing case study, we produced a gear component made from POM (polyoxymethylene) using high-precision machining.

POM is an engineering plastic known for its low friction and high wear resistance, making it well suited for moving components such as gears and bearings where stable operation and long service life are required.

In addition, POM features low moisture absorption, which minimizes dimensional changes even in humid environments. This property ensures high reliability for mechanical components that demand consistent precision and dimensional stability.

From shape verification at the prototyping stage to small-lot production, we offer flexible support and propose optimal gear manufacturing solutions tailored to your application and design requirements.

At INAC, we support the production of high-quality mechanical components by applying machining methods and precision control optimized for material characteristics, including POM and a wide range of other engineering plastics.

Material: POM

Please feel free to contact us.

Adequate support will be provided by our experienced designers until prototype completion.