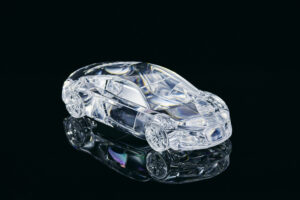

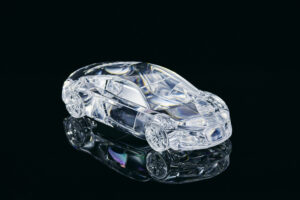

Acrylic Machining Automobile

Acrylic machining Automobile Acrylic Machining Automobile Acrylic Machining Automobile Highly transparent acrylic machining autmobile. Processed with 5 axis machining center. Characteristics Material: Acrylic Please feel

INAC US’s Clear Plastic Resin Machining Service allows you to create transparent prototypes using materials like polycarbonate.

Our expert team employs advanced 3-axis and 5-axis machining centers to shape a variety of materials with precision.

Experience exceptional clarity in your prototypes with our unique high transparency treatment, making INAC US the go-to choice for your clear plastic resin machining needs.

CNC Turning is a machining method that rotates the workpiece and applies a fixed cutting tool to shave it. It is mainly suitable for machining cylindrical parts. With a composite lathe, it is possible to machine complex shapes in one machine by combining lathe and milling operations.

| Material | Description |

|---|---|

| PC(Polycarbonate) | Polycarbonate is an excellent choice for prototyping impact-resistant and transparent parts due to its strength and optical properties. It can be machined, 3D printed, or injection molded, making it suitable for a variety of applications, such as safety equipment, lenses, and lighting components. Our unique transparent processing technology allows us to produce beautiful clear polycarbonate products without requiring extensive polishing work. |

| Acrylic | Acrylic is often used for prototyping transparent parts and models due to its optical clarity and weather resistance. It can be machined, laser cut, or thermoformed, offering versatility in creating intricate designs, especially for light-guiding components, displays, and enclosures. |

| PMMA | PMMA (Polymethyl Methacrylate) is often used for prototyping transparent parts and models, similar to acrylic. Its optical clarity, UV resistance, and weatherability make it ideal for creating prototypes that require a high degree of transparency, such as light-guiding components, displays, and enclosures. |

| PVC | PVC (Polyvinyl Chloride) is commonly used for prototyping pipes, fittings, and other fluid handling components due to its chemical resistance and durability. Its transparency is inferior to that of acrylic or polycarbonate. |

| Material | Density (g/cm3) | Flexural Strength (GPa) | Tensile Strength (MPa) | Izod Impact (kJ/m) |

|---|---|---|---|---|

| PC (Polycarbonate) | 1.15-1.2 | 2.2-2.5 | 61-69 | up to 900 |

| Acrylic | 1.19 | 117 | 69 | 0.4 |

| PMMA | 1.19 | 117 | 69 | 0.4 |

| PVC | 1.3 – 1.45 | 2.67 | 43.2 | 0.442 |

Acrylic machining Automobile Acrylic Machining Automobile Acrylic Machining Automobile Highly transparent acrylic machining autmobile. Processed with 5 axis machining center. Characteristics Material: Acrylic Please feel

ACRYLIC SKULL WITHOUT POLISHING ACRYLIC SKULL WITHOUT POLISHING ACRYLIC SKULL WITHOUT POLISHING Highly transparent acrylic machining even without hand polishing. Processed with machining center. As

Acrylic brilliant cut without polishing Acrylic brilliant cut without polishing Acrylic brilliant cut without polishing This brilliant-cut acrylic model was produced entirely through precision machining

ENGINE VISUALIZATION Visualization of the interior of an engine Engine Visualization Internal visualization of engine and transmission used in automobiles / industrial machines. It is possible to

Resin cutting Brake caliper RESIN CUTTING Internal visualization model using transparent resin machining process technology MATERIALS Polycarbonate, acrylic Visualization of the internal structure for fluid

Transmission Case Transmission case TRANSMISSION CASE Visualization of interior for any mechanical parts Internal visualization for transmissions used in automobiles / industrial machines It is

If you have something you want to make, please contact us. Even a rough idea is OK.

We will give shape to your idea and deliver it to you. Please feel free to contact us.

COPYRIGHT © 2020 INAC US. ALL RIGHTS RESERVED. INAC Inc – PRIVACY POLICY

Liquid casting material is injected into the silicone rubber mold in a vacuum environment.

The silicone mold is cut open into a male and female mold, and the master model is removed.

The master model is fixed to a wooden frame and silicone is poured to create a mold.